Mar 22, 2023

By: Mortaza Pasandideh Quality/Application Specialist, Triangle Fluid Controls Ltd.

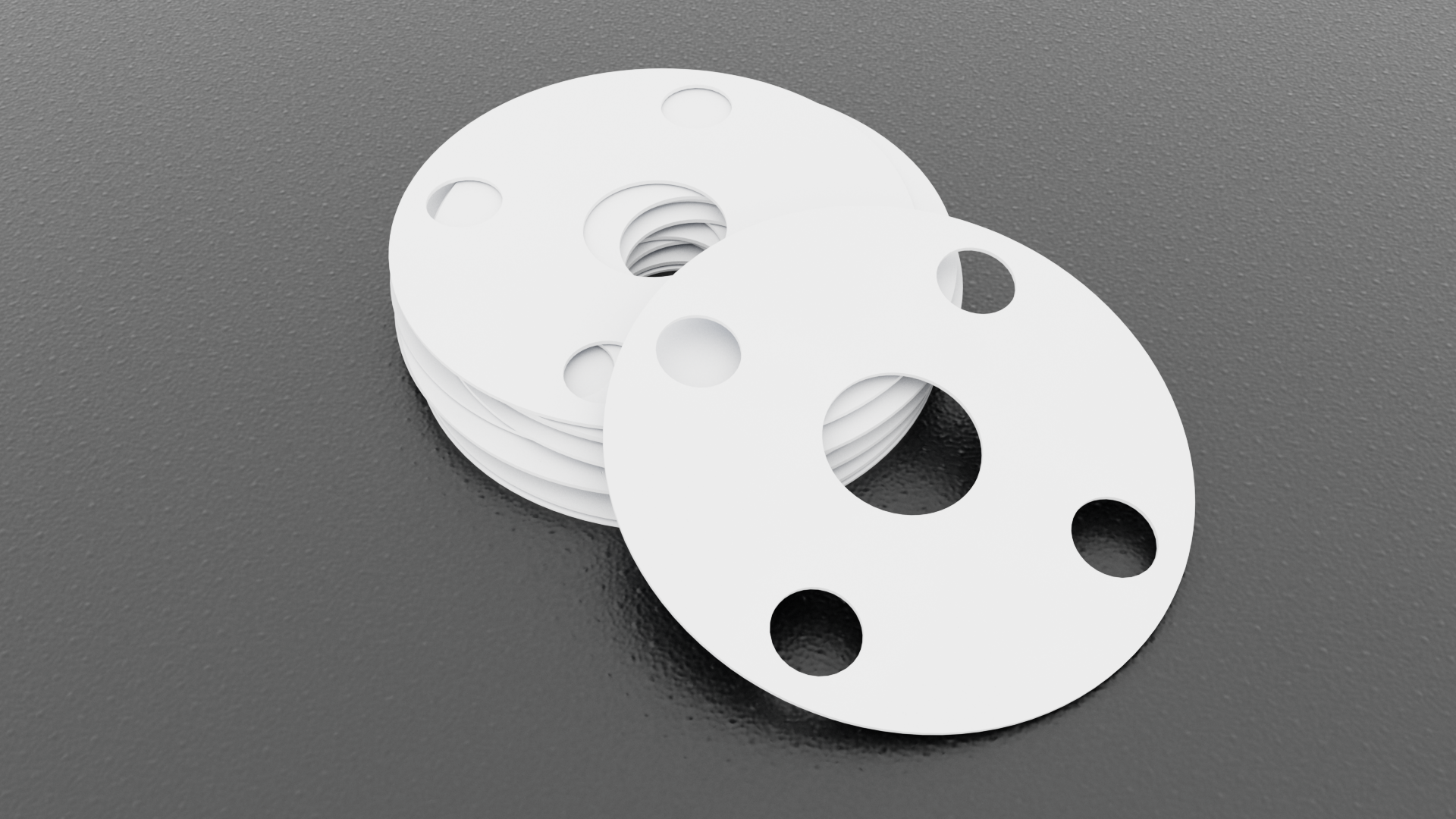

Expanded Polytetrafluoroethylene (ePTFE) is a high-performance sheet gasket material made of multi-directionally expanded 100% Virgin PTFE and used in various industries such as chemical, pharmaceutical, and food processing. It is known for its exceptional resistance to chemicals and high temperatures, making it an ideal choice for sealing applications in harsh environments.

ePTFE gaskets are a popular choice in many industries due to its unique properties, but when it comes to selecting the right gasket material for your application, it is crucial to consider the pros and cons of each option.

Pros

- Chemical resistance: ePTFE gaskets can withstand a wide range of aggressive chemicals, including acids, bases, and solvents. This makes them ideal for applications in the chemical, pharmaceutical, and food processing industries.

- High-temperature resistance: Due to the multidirectional structure, ePTFE gaskets can maintain their mechanical and sealing properties at high pressures and temperatures.

- FDA Compliant: ePTFE is non-toxic, making it safe for use in most of the food and pharmaceutical applications.

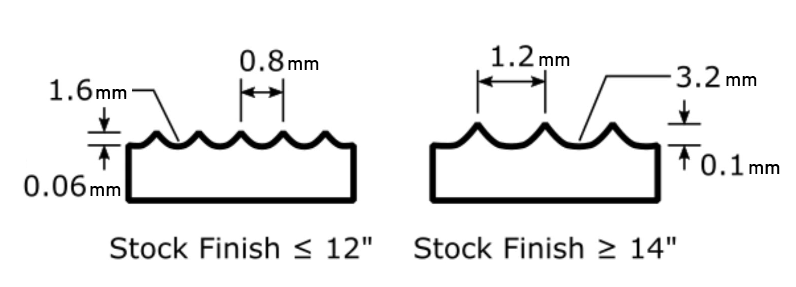

- High compressibility: ePTFE gaskets can conform to irregular surfaces and maintain their seal even under extreme pressure.

- Resistance to creep and cold flow: making it an ideal choice for demanding applications that require a long-lasting, reliable seal.

Cons

- Not suitable for use in abrasive environments: ePTFE gaskets are relatively soft and can be easily damaged by abrasive substances, so they may not be the best choice for abrasive media.

- Requires careful installation or removal: ePTFE gaskets can be easily damaged during installation or removal, which can compromise their sealing ability.

- Expensive: ePTFE gaskets can be more expensive than other gasket materials due to the required complex manufacturing process.

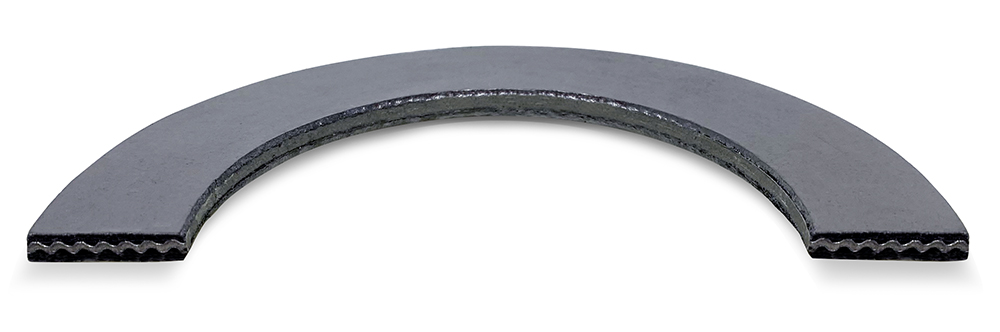

Durlon® Joint Sealant (ePTFE tape) is made from ePTFE sheets and is often used as a cost-effective alternative to ePTFE cut gaskets on flanges with large diameters. This type of sealing can accommodate any flange shape and size, eliminating unnecessary stock inventory.

Durlon® Joint Sealant comes with a self-adhesive backing making the installation process easy for maintenance and overhaul purposes when applying or removing.

Overall, ePTFE gaskets offer a wide range of Pros such as its high chemical resistance, that make them an excellent choice for a variety of applications. However, with Factors such as its high cost, it is important to weigh both the Pros and Cons of ePTFE gasket material before choosing it for a specific application.

Contact our Technical Team for more information about Expanded PTFE (ePTFE) Gaskets.