Jan 21, 2021

By: Bruce Ellis, Inside Sales Consultant at Triangle Fluid Controls Ltd.

What is Thermal Cycling?

Thermal Cycling is the process of alternately cooling & heating material and is often used in manufacturing environments to enhance the material’s properties.

Wafer Check Valves

When a wafer valve is placed in an application that has a wide range of thermal cycling or is exposed to prolonged periods of high temperatures, other system components may be affected. Exposed studs that span from the outside of the flanges on either side of a standard wafer valve, will elongate and can lead to a decrease in bolt load on the gaskets. This will cause the gaskets to leak.

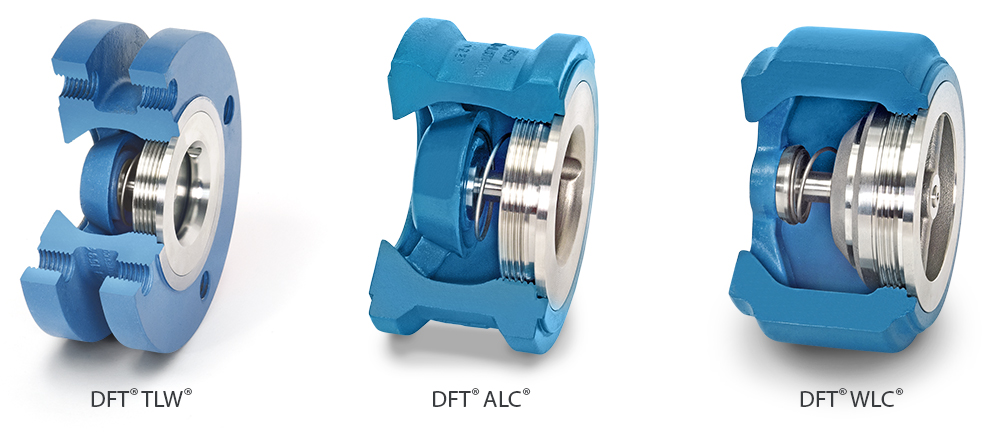

One of the most recent products offering from DFT® is the TLW® (Tapped Lug Wafer valve). This valve is based on the proven wafer designs of the ALC® and WLC® and has many of the same trusted benefits and features, just in a lug style valve.

The TLW® axial flow spring assisted check valve has a one-piece body design that is lightweight and compact. It meets the API 594 face to face dimensions and can be installed in both horizontal and vertical flow applications. The big difference between the standard wafer style valve and the TLW is the tapped design doesn’t have exposed studs which protects the studs from the negative effects of thermal cycling and reduces the opportunities for gasket failure due to stud elongation and relaxation. This style of valve is also suited to fire-safe applications where there is a need to protect bolt exposures as each end of the valve is bolted to the flange similar to the way a flanged valve is.

Conclusion

So, when thinking about valve applications involving high temperature or with a wide range of thermal cycling it is important to consider the valve type itself. The DFT® TLW® might be just the valve you want to use.

See the line-up of DFT® Silent Check Valves here.

Bruce Ellis is an Inside Sales Consultant at Triangle Fluid Controls Ltd. He may be reached at bruce@trianglefluid.com or 613-968-1100.