March 22, 2016

By: Chett Norton, C.E.T

When the conversation turns to gasket selection for high temperatures, things can get a little heated. The truth of the matter is that one person’s idea of a high temperature application is not the same as the next person’s.

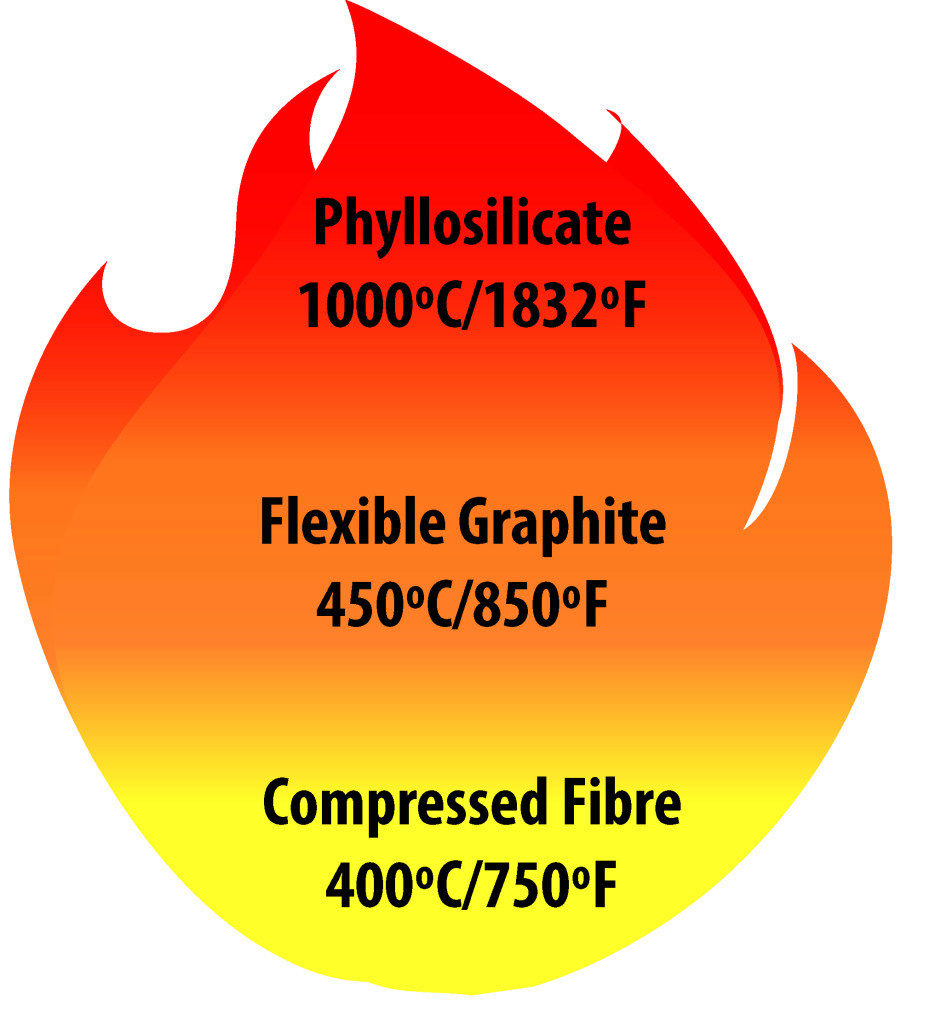

Gasket temperature limits can be classified into (but are not limited to) the following temperature ranges:

Personally, I define high temperature applications as anything that exceeds the limitations of graphite alone. What I mean is that there are high temperature gasketing products such as the Durlon ETG (Extreme Temperature Gasket) series, that use a combination of super inhibited graphite with phyllosilicate materials to design a gasket that performs when exposed to heat and still has excellent sealability. Now don’t get me wrong, there are numerous critical applications that are below the 454°C/850°F threshold that still require high sealing performance at elevated temperatures. Using a gasket that has passed the API 607 Fire Test (with Exxon Modifications), should be taken into consideration when selecting a gasket for elevated temperatures and/or critical applications.

Moderate Temperature Gasketing

Compressed Fibre Gaskets (Max Temp: 400°C/750°F)

Generally these gaskets are found in Class 150# and 300# applications. They perform quite well in low to moderate temperature applications, however, once introduced to elevated temperatures or steam they can become brittle due to their elastomer based binder. This can become problematic as when a gasket becomes brittle, it loses its ability to recover and if used in cyclic conditions, this can cause leaks. If a gasket is retightened after being introduced to temperature it can fracture causing a leak or gasket blowout. New advancements in filler material have allowed materials like Durlon 8900 to be developed that allow an increase in product temperature limitations, without the common brittleness found in other sheet materials. Durlon 8500 & Durlon 8900 have both passed the API 607 Fire Test.

Generally these gaskets are found in Class 150# and 300# applications. They perform quite well in low to moderate temperature applications, however, once introduced to elevated temperatures or steam they can become brittle due to their elastomer based binder. This can become problematic as when a gasket becomes brittle, it loses its ability to recover and if used in cyclic conditions, this can cause leaks. If a gasket is retightened after being introduced to temperature it can fracture causing a leak or gasket blowout. New advancements in filler material have allowed materials like Durlon 8900 to be developed that allow an increase in product temperature limitations, without the common brittleness found in other sheet materials. Durlon 8500 & Durlon 8900 have both passed the API 607 Fire Test.

Moderate – High Temperature Gasketing

Flexible Graphite (Max Temp: 450°C/850°F)

Flexible Graphite has been essential in industrial sealing applications and have been used in sheet gaskets and semi-metallic gaskets (Spiral Wound Gaskets, Kammprofiles and Corrugated Gaskets) for many years. In higher temperatures, graphite begins to oxidize which lessens the amount of material in the gasket (imagine looking at a piece of Swiss cheese). There are many factors that influence graphite oxidation such as graphite purity, density and surface area exposed to the oxidizing environment. Newer developments and additives such as oxidation inhibitors, slow down the rate of oxidation of graphite and can actually extend the temperature range of the material to 537°C/1,000°F. Such grades of graphite are classified as inhibited or super inhibited graphite (which is also known as Shell spec graphite). All Durlon semi-metallic gaskets have been manufactured using Shell Spec. graphite since late 2015.

High Temperature Gasketing

Phyllosilicate (Max Temp: 1,000°C/1,832°F)

When I think of high temperature applications, I think of gas turbines and burners, heat exchangers, exhaust manifolds and others commonly found in the refinery, power generation and chemical industries.

Phyllosilicate is a good choice when selecting a gasket for high temperature applications, for the following reasons:

- It’s flexible

- It’s elastic

- It has a high tensile strength

- It can withstand substantial mechanical pressure perpendicular to the lamellar plane

- It’s chemically resistant

- It’s fireproof

- It’s infusible

- It’s incombustible

- It’s non-flammable

- It’s a reliable alternative to asbestos

Durlon HT1000 consists of phlogopite mica “paper” impregnated with an inorganic binder at less than half the binder, amount found in vermiculite filled products. This lower binder content allows for superior weight retention, less than 4% weight loss at 800°C (1,472°F) and results in ultimate extreme temperature sealing performance up to 1,000°C (1,800°F).

So what does that mean?

In basic terms, it means that there will be more material present at higher temperatures, thus the leakage will be less than with other materials.

Final Thoughts

Hopefully this is a good jumping off point to aid in your search for high temperature gasket material. Just know, that this only begins to scratch the surface when trying to select a material for your critical application. As always, I would suggest contacting the gasket manufacturer to make sure you are using the best gasket material for your application. If you would like my help selecting a high temp gasket for your critical application, then complete and submit a Gasket Application Data Form. If you have any questions or comments, reach out to me as I am always up for discussing gaskets. You can find me on Twitter @TFGGasketguru or email me at tech@trianglefluid.com and bring the question heat!

Until next month, stay safe and keep the fluid between the pipes!

Additional Resources:

Gasket Installation Video

Gasket Fundamentals