Dec 3, 2020

By: Bruce Ellis, Inside Sales Consultant at Triangle Fluid Controls Ltd.

What is meant by check valve sizing?

Sizing a centre guided valve is not difficult. Along with the pipe size, pressure class, and type of valve required (flanged, wafer, etc.), users need the actual working pressure, flow rate, media type, temperature, and the specific gravity of the media. It may be as simple as building the valve with a lighter spring to allow the valve to fully open. In order for the valve to reach the full open position, it may need a lift limiter to reduce how far the disc travels. When the valve is 100% open, it will be stable in the flow and will result in reduced premature wear and failure by eliminating the effects of chatter. It is very important to remember; these valves are designed to the actual flow values and not to the line size. A properly sized valve will be in either the full open, or closed positions.

Why size a valve?

Benefits of using a properly sized and positioned silent check valve:

- It can protect a system from costly failures and down-time of a production facility.

- The valve life span can be greatly increased by reducing the risk of parts breaking off and damaging equipment downstream.

- It protects the pumps that are upstream by not allowing backflow which can severely damage the pump as it can spin in the reverse direction.

- It leads to better pump and compressor protection.

- It results in less piping vibration.

- There is a reduction in Water Hammer issues.

- It will work in the vertical down flow direction.

Return on investment

Initial “sticker shock” for a sized valve, in many cases can be scary, so we need to ask ourselves a few questions:

- How long does the off-the-shelf valve last?

- What does it cost to change it?

- How much revenue is lost while it is being replaced?

Replacing a valve can be quite costly based on the effects of lost revenue, wages, and the cost of the replacement valve. The price of an off-the-shelf valve may be attractive, but what is the real cost of ownership? If a sized valve costs five times as much but lasts five times as long, consider how these affect your financial balance given maintenance costs and lost production.

Conclusion

While there are applications where double-door and swing check valves operate properly and are required, it is not true that these and other off-the-shelf valves are the only solutions. In any application where check valves are being used, having the correct valve installed could enhance the performance and extend the lifespan of the piping system, affecting the financial balance when adding maintenance costs and lost production. This translates into more value and overall, long term cost savings.

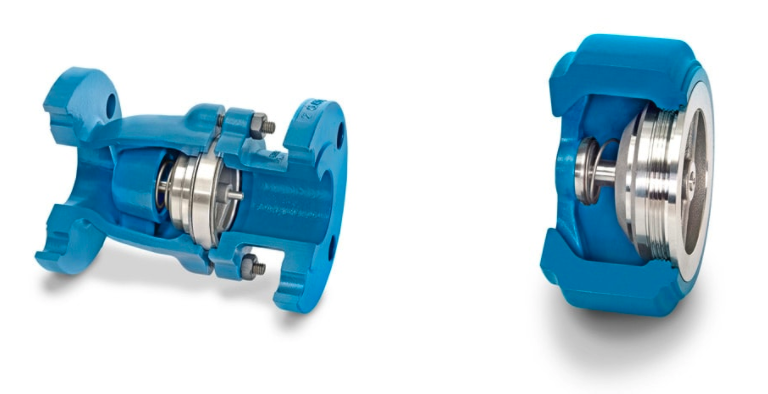

See the line-up of DFT® Silent Check Valves here.

Bruce Ellis is an Inside Sales Consultant at Triangle Fluid Controls Ltd. He may be reached at bruce@trianglefluid.com or 613-968-1100.