Oct 26, 2022

By: Mortaza Pasandideh Quality/Application Specialist, Triangle Fluid Controls Ltd.

Gaskets are used in flange joints to prevent leakage. It is necessary for all gasket materials to have enough flange pressure to compress the gasket to form a tight, unbroken seal. The number, size, and grade of bolts used in the application determine the bolt load available. However, the leakage in bolted flange connections is significantly influenced by the sealing surface’s contact area. Low-stress sealing systems typically have little tolerance for high bolt torque to avoid damage to the flange.

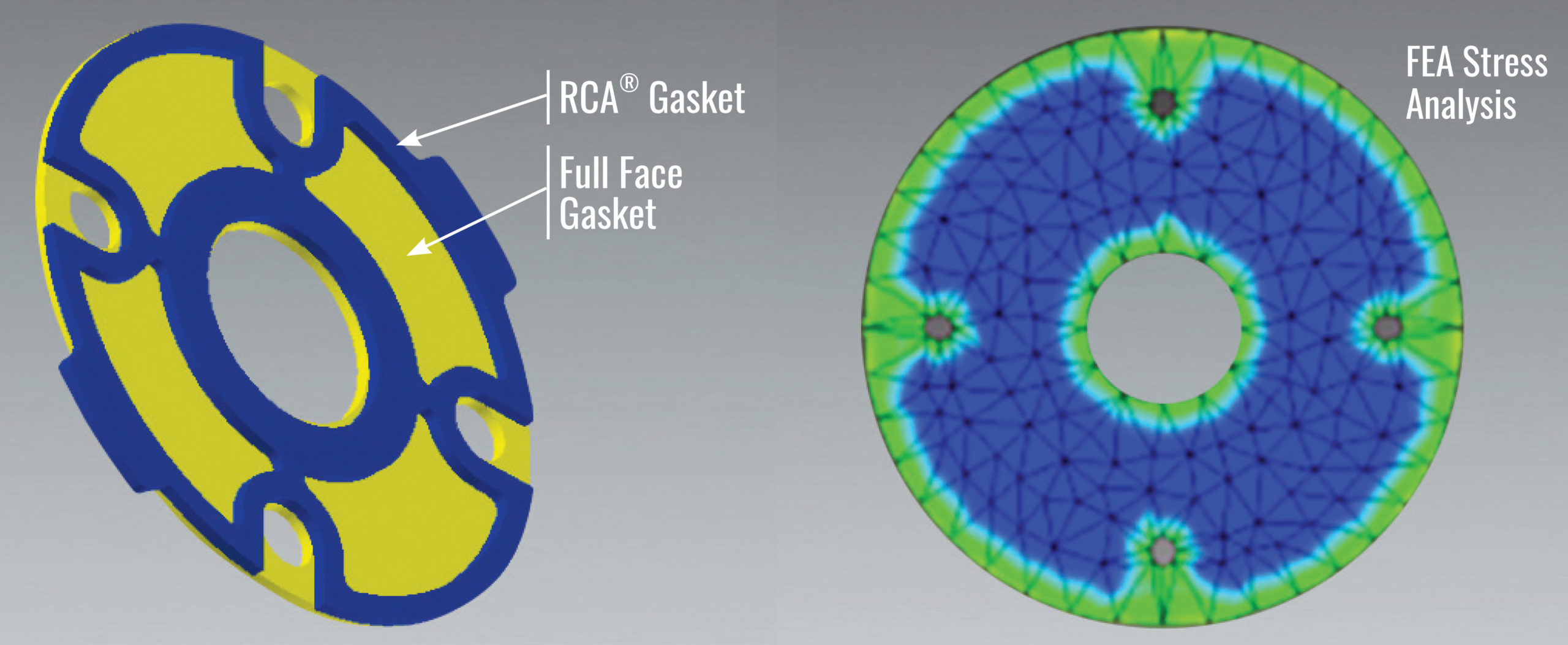

“Reduced Contact Area ” or RCA® Gasket design is an effective solution to get the best low-torque seal in load-compromised applications. The contact area of the flanges in a sealing system is fixed, regardless of the type and form of the gasket. Any acceptable gasket material has a predetermined minimum stress requirement which is a function of operating pressure. Additionally, the maximum permitted bolt torque dictated by gasket material, bolt material, or flange material is also fixed and cannot be changed. The gasket geometry design and the consequent surface area is the only variable left. The sealing concept behind the RCA configuration is to reduce the total sealing contact area resulting in a higher gasket stress at a given bolt load while preventing flange rotation. RCA gaskets are ideal for brittle, non-metallic flanges where the excessive assembly bolt load required to compress the standard full-face gasket is not available. RCA gaskets are suitable for FRP, PVC, PVDF, Cast Iron & API manways. They provide leak-free performance without the hassle of cracked flanges.

Durlon® Reduced Contact Area Gaskets (RCA) are available in standard 1” to 24”, Class 150#, Full Face sizes. They can be cut from Durlon® PTFE, Compressed Non-Asbestos material, HT1000®, and Flexible Graphite sheets. RCA gaskets fabricated from selected Durlon PTFE are oxygen service qualified and conform to FDA requirements. Additionally, installation of RCA gaskets is easy because they have identification tabs and alignment guides. Since RCA gaskets can be cut from standard sheets, compared to other low-stress gaskets, they are cost-saving sealing solutions for the end users.

The below graph illustrates a 3” 150# Full Face gasket using FEA analysis to show the applicable stresses that are being applied to the gasket while bolted up in the flange. The gradual shades of grey (from light to dark) show stress intensity. Blue indicates very little, or no stress is being applied at all to those areas of the gasket.

Features and Benefits

- Low Seating Stress

- Leak-free performance in low bolt-stress applications

- Protecting the flange from cracking

- Easy identification and installation

- Conformability to a wide variety of sealing surfaces and irregular surfaces

- FDA and Oxygen service qualified options as well as high-temperature styles available

Contact our Technical Team for more information about Low Seating Stress Gaskets.