Mar 30, 2021

By: Samantha Harrison, QA/Applications Specialist

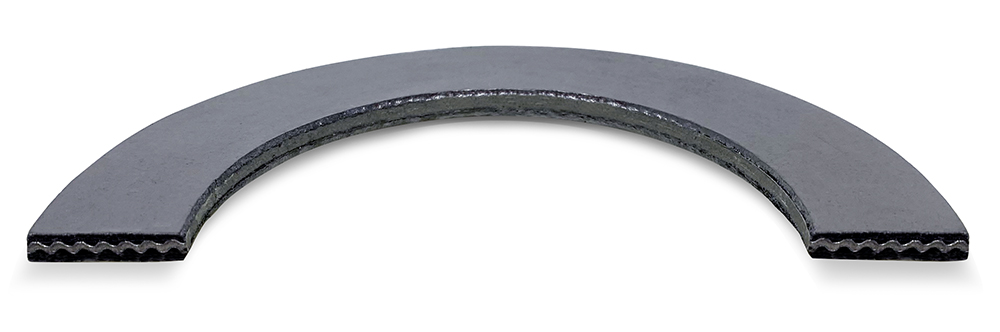

There’s a buzz in the sealing industry about our Durtec® gasket. So, what’s a Durtec®, you ask? Very simply, it’s the combination of a corrugated metal gasket and a Kammprofile, on steroids! The Durlon® Durtec® is the next-generation semi-metallic gasket featuring a corrugated profile, based on our proprietary machined core, allowing for a tighter seal at lower bolt loads and zero retorquing.

The Durtec® gasket is universally used in a wide range of applications, including high-temperature applications (ETG configuration), aggressive chemicals (PTFE facing), vibration, and severe cycling applications where previous spiral wound gaskets were used and proven problematic. What makes the Durtec® so special is that it has excellent sealing features; a key factor when you have applications that are not easy to get to or are in remote field applications.

So, let’s review the many advantages of using a Durlon® Durtec® and why it is referred to as the universal choice for all your sealing needs:

- API 607 4th edition Fire safe Certified, with zero leakage

- Excellent Blow Out resistance due to the machined core

- Cost-effective because it can be resurfaced, if not damaged

- Can replace both Spiral Wound and Kammprofile gaskets, improving longevity and reducing inventory by consolidation

- Seals with a lower bolt load compared to Spiral Wound and Kammprofile gaskets due to our proprietary machined core, resulting in lower overall fugitive emissions

With our various Durtec® gasket configurations, we can offer many sizes, types, and material options:

- We can manufacture standard ASME, DIN, JIS, and BS EN sizes as well as Non-standard sizes up to 157” (4m) in diameter.

- The standard core material is 316LSS but can be manufactured for almost any metal including 304SS, 317SS, 321SS, 347SS Inconel 600/625/750/800, Hastelloy C276, Alloy 20, Monel, Duplex 2205/2507, Nickel 200, Titanium, Zirconium and many other materials upon request, readily available or on-hand.

- Our Standard facing material is super-inhibited flexible graphite that meets or exceeds Shell Specification MESC SPE 85/203, extending the upper operating temperature from 850ºF (454ºC) to 1022ºF (550ºC). Alternate facing materials are available upon request such as Durlon® 9000 & 9600 (for aggressive chemical applications), and our ETG (Extreme Temperature Gasket) series & HT1000® for high-temperature applications.

So, if you’re an engineer, pipefitter, plant, or maintenance manager, you can benefit from choosing a Durlon® Durtec® gasket for any suitable application. If you’re still uncertain, send us an email with the application data and we will review it and determine which Durtec gasket configuration is best for your sealing needs.