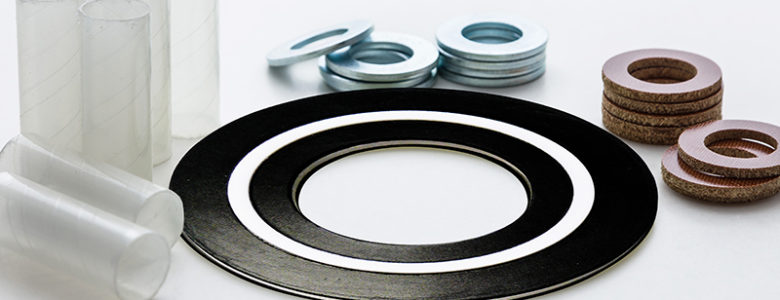

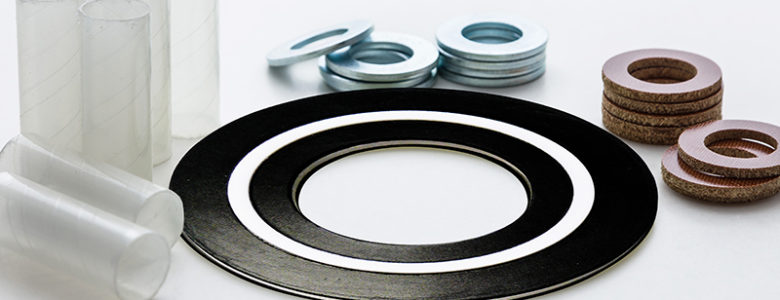

Durlon® iGuard™ flange isolation and sealing systems consist of all the necessary components to seal, electrically isolate, and cathodic protection (corrosion control) between flanges in general to severe service applications such as water, wastewater, natural gas, hydrocarbons, caustics, acids, and other aggressive media to 232°C (450°F). Gaskets are available for full face (Type E), raised… Read More »

Durlon® iGuard™ flange isolation and sealing systems consist of all the necessary components to seal, electrically isolate, and cathodic protection (corrosion control) between flanges in general to severe service applications such as water, wastewater, natural gas, hydrocarbons, caustics, acids, and other aggressive media to 232°C (450°F). Gaskets are available for full face (Type E), raised… Read More »

Durlon® iGuard™ flange isolation and sealing systems consist of all the necessary components to seal, electrically isolate, and cathodic protection (corrosion control) between flanges in general to severe service applications such as water, wastewater, natural gas, hydrocarbons, caustics, acids, and other aggressive media to 232°C (450°F). Gaskets are available for full face (Type E), raised… Read More »

Durlon® iGuard™ flange isolation and sealing systems consist of all the necessary components to seal, electrically isolate, and cathodic protection (corrosion control) between flanges in general to severe service applications such as water, wastewater, natural gas, hydrocarbons, caustics, acids, and other aggressive media to 232°C (450°F). Gaskets are available for full face (Type E), raised… Read More »

The TLW Check Valve (Tapped Lug Wafer) was engineered for applications where exposed studs are not suitable. This non-slam spring-assisted, center-guided, lugged pattern wafer check valve is designed to prevent water hammer and reverse flow. The lightweight compact design fits between mating flanges and meets API 594 face-to-face dimensions. The TLW Check Valve body design… Read More »

The DFT® Excalibur® NAB (Nickel-Aluminum Bronze) Silent Check Valve is a spring-assisted, nozzle style, non-slam check valve and designed to withstand the harsh environments of salt and brine water applications where corrosion resistance and marine life deterrents are a must. DFT’s centre guided check valves provide reliable, low-maintenance service and solve the problems associated with… Read More »

Application: Durlon® 9000N is used extensively in chemical, pulp and paper, food and beverage and the railroad tank car industries. It has been tested and approved for liquid chlorine, caustics, liquid oxygen, and high purity applications in the pharmaceutical industry (blood components manufacturing). Durlon® 9000N is designed for applications where resistance to highly aggressive chemicals is required and conforms… Read More »

Considering the environmental climate of today, it is more important than ever to prevent leakage in your piping systems. With flanges being the most common trouble area, proper sealing is key to preventing leakage. Durlon® offers quality products and materials which can help solve most flange sealing problems from eliminating leakage to preventing corrosion and… Read More »

Application: Durlon® 9002 is an adaptation of the original glass-filled formula to better meet extreme cryogenic system demands. Durlon® 9002 has passed both gaseous, [up to 260°C (500°F) and 52 bar (754 psi)] and liquid oxygen tests performed by BAM Federal Institute for Materials Research and Testing. Durlon® 9002 has also been tested for LOX… Read More »

Application: Durlon® 8900 is a premium grade compressed non-asbestos sheet gasket material for service conditions to 496°C (925°F) and continuous operating temperatures of -73ºC to 400°C (-100ºF to 752°F) or 13.8 MPa (2,000 psi). It is suitable for water, saturated steam, superheated steam, oil, mild alkalis and acids, hydrocarbons and solvents. Composition: Durlon® 8900 was specially… Read More »

Application: Durlon® 5000 is a Commercial grade gasket material for moderate service conditions. It contains high strength mineral fibres and fillers bonded with NBR. Composition: Durlon® 5000 contains mineral fibres bonded with nitrile (NBR) synthetic rubber. A release agent on both sides provides good anti-stick properties. Anti-stick properties: Much effort has gone into improving the… Read More »

Application: Durlon® Spiral Wound Gaskets (SWG) are made with an alternating combination of a preformed engineered metal strip and a more compressible filler material which creates an excellent seal when compressed. The engineered shape of the metal strip acts as a spring under load, resulting in a very resilient seal under varying conditions. Composition: The… Read More »

A highly fibrillated expanded PTFE form-in-place sealant for gasketed joints. Supplied on spools, it is not dependent on flange dimensions. Durlon® Joint Sealant comes in various thicknesses with a high quality adhesive backing to ease in installation and is ideal for worn flanges of all sizes. It exhibits flexibility, compressibility, stability under high temperature and… Read More »

Application: Durlon® Extreme Temperature Gaskets (ETG) have been engineered to provide the preeminent solution to sealing gasketed joints having exposure to high temperatures, typically greater than 650°C (1,200°F) and up to 1,000°C (1,800°F). At extreme temperatures, flange assembly torque retention is the key component to maintaining a tight seal. Durlon® ETG has combined an oxidation… Read More »

Application: Durlon® Durtec® gaskets are made with a specially engineered machined metal core that is bonded on both sides with soft covering layers, typically flexible graphite. The core is produced by proprietary technology that allows the finished gasket to have the best possible mechanical support function. The Durtec® core is virtually un-crushable unlike conventional corrugated… Read More »