March 13, 2018

By: Chett Norton, C.E.T.

As a gasket application’s engineer, I spend a lot of time speaking with people on the phone or in person on site discussing gaskets. Whether it is material selection, installation or trouble-shooting gasket failures, there are many common things I hear people talk or ask about. So, this month I am writing to try and clear the air and help shed some truth on common things that are either thought to be true or practiced in field.

1. Thicker gasket material is better

People generally request thicker material due to an excessive gap or misaligned flanges. They think that the thicker material will fill the void; however, what they may not be aware of is creep/relaxation. Gasket creep/relaxation is somewhat linear (depending on the material) and the amount of material creep increased with gasket thickness. Want less creep, go thin or go home! Also, things such as torque retention, higher blow-out resistance and leakage (through gasket permeation) are much better with thinner materials.

2. Gasket colours indicate the materials are the same

”I’ve always used a blue gasket, so I need a blue gasket” is a common phrase heard time and time again. Gasket colour is generally meaningless. But in some cases, competitors may choose the same colour for their entire product line. So, to be sure, instead of asking for a specific colour, verify the pressure, temperature and media so that the proper material will be selected for your application.

3. Torque values are the same for all gasket materials

All torque values are not the same. Firstly, when looking at torque charts please be sure to read the fine print to verify bolting material, % of bolt yield used, K-Factor used and the maximum allowed compression for each material. For most soft gaskets, the maximum gasket compression is 15,000psi, however for semi-metallic gaskets like SWG’s and Kammprofile’s the maximum compression is more like 20,000-30,000 psi so there is good chance you could possibly crush the gasket if you use an incorrect value.

4. Leaking gaskets just need to be retightened

If a gasket is leaking, do not retighten. Particularly with soft gasket materials, hot torqueing is very dangerous. Once compressed gaskets reach an elevated temperature they can become brittle and further tightening can cause the gasket to crack. This can further increase the leak or even worse, cause a gasket blow out! If a gasket is leaking, it should be replaced!

5. All gaskets are made the same and perform the same

Not true. There are many types of methods for the manufacturing of sheet materials such as the calendar method, skived method and even the beater add which all give the material different properties. The properties shown on gasket technical data sheets are for QC purposes and allow you to somewhat compare “apples to apples” however they do not actually give you performance data but are merely indicators on how they may perform in certain applications. There are some tests out there like the FSA Steam test which are representative data on how the product will perform in steam applications. There are others for specific properties so be sure you are understanding the correct test values and how they will benefit or affect your sealing application. And you may want to use the materials ASTM F104 line call to truly compare gasket materials because it is the preferred method to ensure you are on a level playing field.

6. Grease or lubricant is a good way to hold a gasket in place during the installation process

Getting a gasket into position during an installation can be tricky, so sometimes people use a dab of grease or lube on the gasket to get it to stick to the sealing face during bolt up. This is not a good idea for two reasons: the grease can chemically attack the gasket material and it also lubricates the sealing face which allows the gasket to be pushed out easier by the system pressure. Now remember, we are trying to compress the gasket enough to fill the flange serrations and have them “bite into” the gasket to resist being pushed out by the system pressure. Putting grease on the gasket negates what we are trying to achieve…..so don’t do it!

7. Softer materials seal better

Firmness is also referred to as the materials ability to resist flow. Softer materials are not necessarily better, but they are good for applications where the material needs to confirm to worn flanges or uneven flanges. It is quite common for the material to have more creep when softer, so this may not be a desirable trade off when choosing the material. For higher temperature and higher pressure applications, material hardness and sealing surface finish need to be strongly considered.

8. Gasket installation procedure doesn’t affect sealing performance

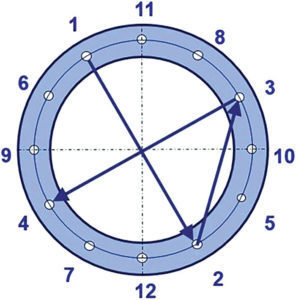

Gasket installation is the most influential factor that affects sealing performance. If you do not install the gasket using a correct method such as the Legacy Method (see figure 1), an alternative method listed in ASME PCC-1, Appendix F or the method recommended from the manufacturer, you run the risk of not getting the most out of your gasket. Using a proper installation method helps the installer bring the flanges together in parallel which lessens the risk or crushing the gasket or unevenly loading the gasket which can cause leaks. Furthermore, it ensures that the load applied to the gasket (via torqueing) is correct and consistent which is important in gasket sealing performance.

Figure 1. Legacy Method Bolt Tightening Pattern

So, there you have it, hopefully this sheds some light on some common myth’s when selecting or installing gaskets. If you have one that wasn’t covered, feel free to drop me a line at tech@trianglefluid.com or @TFCGasketguru on twitter and we will get you on your way to better sealing!

Until next time, keep the fluid between the pipes.

Download the Durlon® Gasket Manual now!