April 26, 2018

By: Bruce Ellis, Inside Sales and Sylvia Flegg, Marketing Manager

There is an ever-increasing demand for dependability, efficiency and energy savings when selecting valves – as it needs to be the correct one! And a function that is often overlooked is the valve’s ability to minimize energy consumption.

Principles of Operation

An essential element in the design of pumping systems is the proper selection of the pump discharge check valve, whose purpose is to automatically open to allow forward flow and automatically return to the closed position to prevent reverse flow when the pump is not in operation.

Check valves are generally made up of plastic or metal. In most sanitary applications you will find the composition of the valve being 316L stainless steel and are CIP (Clean In Place) capable.

Cracking pressure (the minimum upstream pressure at which the valve will operate) is also an important design element of the sanitary check valve.

When selecting a sanitary check valve, you should look at the following criteria:

- Non-slamming characteristics

The amount of time it takes for the Check Valve to close and the way in which the disc travels from the open to the closed position. - Disk design

Location is a key factor here. - Cost

Is the initial purchase price competitive? The main things a buyer should consider are system downtime, valve location and cost of parts and labor. - Application

The importance of each selection criteria must be weighed to make an informed selection on the valve best suited for the application.

Our solution – the DFT® DSV® Sanitary Check Valve

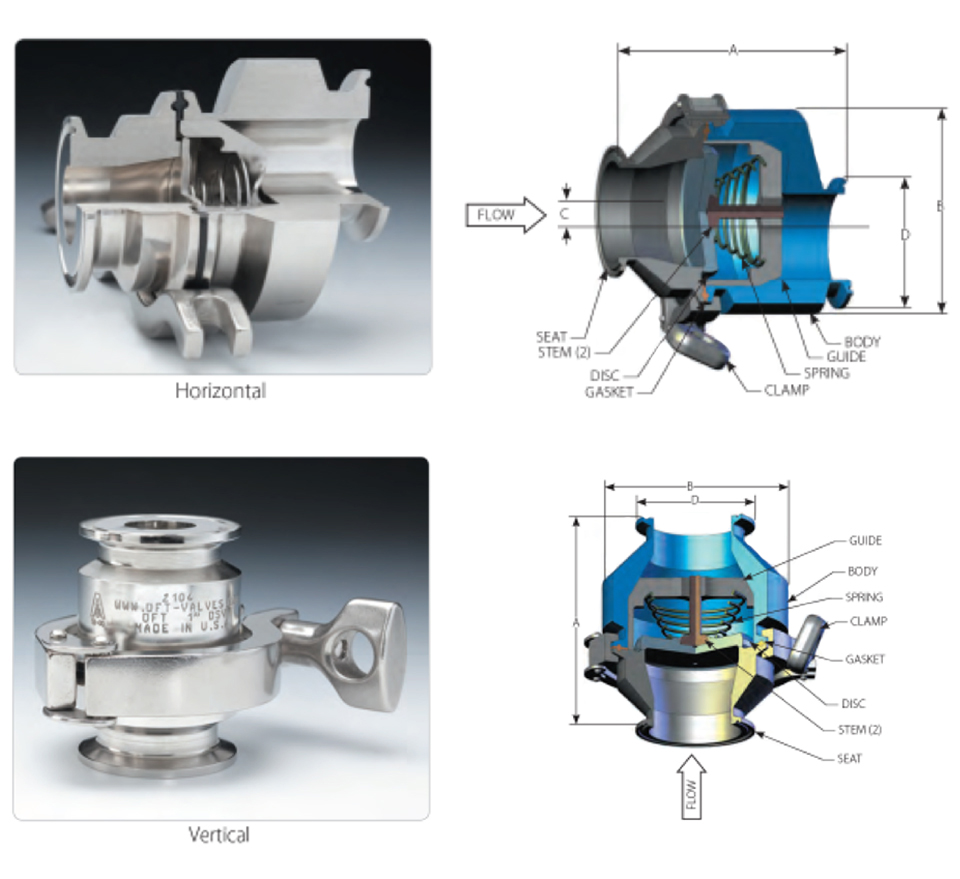

The DSV® Sanitary Check Valve is an edge/centre guided disc design valve for applications where CIP designs are required.

They are used mainly in food, chemical & cosmetic factories. These valves are available in horizontal (self-draining) and vertical styles.

The DSV® valve meets USDA and 3A Sanitary Standards and Pharmacopeia (USP Class VI) certifications.

The valve itself is manufactured from 316 stainless steel polished to 25RA and is available polished to 15RA and is fastened with a quick release clamp and elastomeric body seal to permit fast and easy access to the internals. The disc and seat are lapped to provide excellent shutoff.

Features:

- 1/2” to 4” line size

- 150 CWP, 108 ASME pressure class

- Meets 3A Standard 58-01

- CIP (Clean In Place)

- Clamped ends

- 316L body and seat

- 316 disc, spring & guide assembly

- 32 Ra internal surface finish (#4 Ground Finish)

- Electropolished spring (.16 to .66 psig cracking pressure)

- EPDM body seal (300°F max temp.)

- Edge-guided disc (1/2” thru 2”)

- Edge/Center-guided disc (2-1/2”, 3”, 4”)

- Spring assisted silent closing, non-slam

- Tight shutoff – lapped disc & seat

- Horizontal or vertical installation

Options:

- 15 Ra internal finish

- Tuf-Flex® or Viton® body seal

- Straight thru inline or offset inlet/outlet

Download the DFT® Silent Check Valve 6-page Brochure now!