View this detailed comprehensive brochure of our product offerings for use in extreme temperature applications. Download here.

When exposing industrial bolted joints to extreme temperatures and pressure, you need to have the right gasket that not only provides effective sealing but lasts longer. Gasket temperature limits can be classified into (but are not limited to) the following temperature ranges: Phyllosilicate 1000ºC (1832ºF), Flexible Graphite 450ºC (850ºF), Compressed Fibre 400ºC (750ºF).

High-temperature applications such as gas turbines, heat exchangers, exhaust manifolds and others commonly found in the refinery, power generation, and chemical industries, Phyllosilicate is a good choice for the following reasons:

- high tensile strength

- low weight loss at extreme conditions

- laboratory tested for fire safety

- non-combustible

- sustainable solution

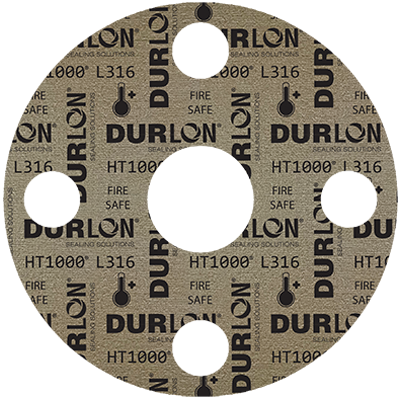

HT1000®

Durlon® HT1000® consists of phlogopite mica paper impregnated with an inorganic binder at less than half the binder amount found in vermiculite-phyllosilicate filled products. This lower binder content allows for superior weight retention, less than 4% weight loss at 800°C (1,472°F), and results in ultimate extreme temperature sealing performance up to 1,000°C (1,832°F). Durlon® HT1000® characteristics allow for it to be used as a sealing material on its own or combined with various carrier media in heat exchangers, exhaust manifolds, and other equipment commonly found in the refinery, power generation, and chemical industries.

Phlogopite mica is a non-toxic naturally occurring hydrated silicate of potassium and magnesium with a lamellar and non-fibrous structure. It is flexible, has high tensile strength, can withstand substantial mechanical pressure perpendicular to the lamellar plane, is chemically resistant, fireproof, infusible, incombustible, nonflammable, and is a known alternative to asbestos.

Style S90

Phlogopite mica paper impregnated with an inorganic binder and no carrier.

Style L316

Phlogopite mica paper impregnated with an inorganic binder laminated with a 0.002” thick 316 stainless steel carrier.

Style T316

Phlogopite mica paper impregnated with an inorganic binder laminated with a 0.004” thick 316 stainless steel perforated carrier.

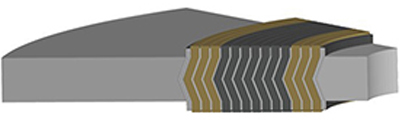

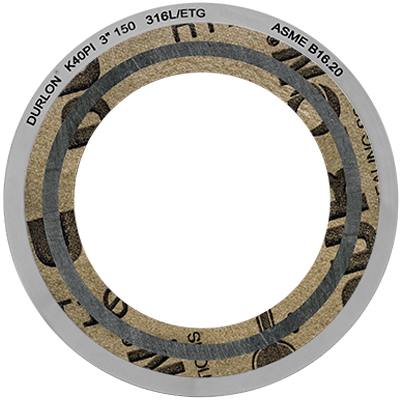

DRI-ETG SWG

Durlon® Extreme Temperature Gaskets (ETG) have been engineered to provide the preeminent solution to sealing gasketed joints having exposure to high temperatures, typically greater than 650°C (1,200°F) and up to 1,000°C (1,832°F). At extreme temperatures, flange assembly torque retention is the key component to maintaining a tight seal. Durlon® ETG combines an oxidation boundary material with the excellent stability and sealing characteristics of flexible graphite in order to preserve seal integrity and retain the initial assembly torque.

Durlon® ETG adds an inner and outer protection boundary in the form of a mica-phyllosilicate based sealing material called Durlon® HT1000® which consists of phlogopite mica paper impregnated with an inorganic binder at less than half the binder amount found in a typical vermiculite-phyllosilicate filled product. This lower binder content allows for superior weight retention and results in ultimate extreme temperature sealing performance.

Durlon® Spiral Wound Gaskets are made with an alternating combination of a preformed engineered metal strip and a more compressible filler material which creates an excellent seal when compressed. The engineered shape of the metal strip acts as a spring under load, resulting in a very resilient seal under varying conditions. The strip metallurgy and filler material can be selected to seal a wide range of applications. All Class 150 & 300 Durlon® SWG styles have been engineered to precise manufacturing tolerances and utilize optimal winding density that allows for lower stress (bolt load) sealing compared to conventional spiral wound gaskets thus eliminating the need to stock both standard and low stress SWG’s.

Style DRI

Sealing element (D) combined with a centering ring (R) and an inner ring (I) which improves radial strength and protects the sealing element from erosion and inward buckling.

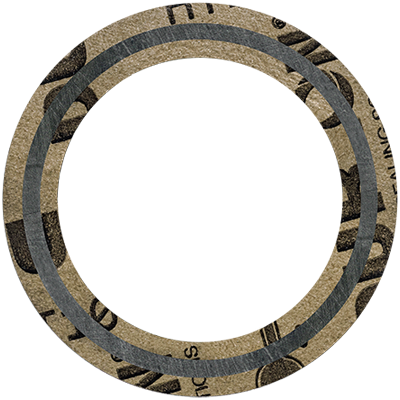

K40-ETG Kammprofile

Durlon® Kammprofile gaskets have a solid metal core with concentrically serrated grooves machined into the top and bottom faces. The metal core is typically stainless steel, but it can be supplied in various metallurgies as per the customer’s request.

The serrated core is covered with soft sealing material and is dependent on the service conditions of the system. Flexible graphite and expanded PTFE sealing layers are most common, but other products like HT1000® or (Extreme Temperature Gaskets) ETG’s can be used as well. While providing the Durlon® Kammprofile gasket with excellent sealing properties, the soft sealing layers also fill in minor flange imperfections and protect the flange surfaces from damage.

Durlon® Kammprofile gaskets are the preferred choice for applications requiring improved performance at low seating stresses. The serrated peaks provide reduced contact area and when combined with the soft conformable sealing layers, the Durlon® Kammprofile gasket provides a virtual metal to metal connection. They feature excellent resistance to blowout and provide superior stability for ease of handling and installation.

Durlon® ETG’s engineered design principle is focused around providing oxidation protection zones around the central oxidation inhibited flexible graphite sealing component. Standard industrial-grade flexible graphite typically begins to rapidly oxidize at around 650°C (1,200°F). By adding oxidation inhibitors to the graphite, the rate and amount of oxidation can be significantly reduced, thus extending the seal life of the material. However, oxidation can still occur and at extreme temperatures, it can be fatal to the integrity of the joint.

Core materials are generally selected in an identical material to the piping system in order to reduce corrosion problems. The standard core material is 316 stainless steel with a nominal thickness of 0.125” (3mm). Other core materials: SS304, SS321, SS316Ti, Monel®, Titanium, Hastelloy® & Alloy 20 can be manufactured to your specifications on request.

Parallel Root Core

This core design is where the main sealing faces of the serrated metal core are parallel to each other. These are the standard design of Kammprofile gaskets.

Integral Centering Ring

The centering ring is used to position the gasket between flat face and raised face type flanges.

Durtec® ETG

Durlon® Durtec® gaskets are made with a specially engineered machined metal core that is bonded on both sides with soft covering layers, typically flexible graphite. The core is produced by proprietary technology that allows the finished gasket to have the best possible mechanical support function. The Durtec® core is virtually uncrushable, unlike conventional corrugated metal core gaskets. The precision construction guarantees that Durlon® Durtec® gaskets will have excellent sealing characteristics even under low bolt loads.

The Durtec® gasket is designed to withstand high temperatures and pressures, to be blowout resistant, to be fire safe, and to resist toxic and or corrosive chemicals for such applications as pipeline flanges, valves, small & large pressure vessels, heat exchangers, towers, and tanks.

Core Materials

Standard core material is 316 stainless steel with a nominal thickness of 0.125” (3mm). Other core materials: SS304, SS321, SS316Ti, Monel®, Titanium, Hastelloy® & Alloy 20 can be manufactured to your specifications on request.

HT1000® Paste

Durlon® HT1000® Paste is a sealing compound designed to be used in conjunction with our HT1000® sheet material specifically for large dovetail gaskets. The paste allows end users to create larger diameter gaskets using cost effective dovetail gasket segments. The HT1000® Paste allows end users to eliminate possible leak paths of traditional dovetail gaskets, while providing end users the one piece gasket construction and lower leakage rates similar to one-piece gasket.

CONTAINER SIZES: 170 g and 90 g.

Testing Results

Two types of 4-inch Class 600 Inconel 625 spiral wound gaskets (with Inconel 625 bolts and washers) were prepared for this testing procedure: one with ETG configuration and one using HT1000 filler entirely. The gaskets were tested at 14,500 psi and 25,000 psi gasket stresses according to the following procedure:

- 1. Test assembly was calibrated for pressure drops vs. volumetric leak rate.

- 2. The assembly was pressurized with nitrogen to 150 psig and leakage was measured.

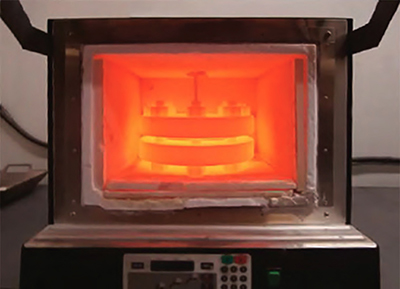

- 3. The entire assembly was heated in the oven to 1382°F and was held for 24 hours.

- 4. After stabilization, the leakage was recorded by pressure decay method.

- 5. The assembly then was cooled to the ambient and pressurized with nitrogen to 150 psig to measure the leakage one final time.

| Temperature (oF) | Leakage (ml/min) | Leakage (ml/min) | Leakage (ml/min) | Leakage (ml/min) |

| – | 4” 600# 625/ETG | 4” 600# 625/ETG | 4” 600# 625/HT1000 | 4” 600# 625/HT1000 |

| – | 14,500 psi | 25,000 psi | 14,500 psi | 25,000 psi |

| 1382 | 0.032 | 0.016 | 0.45 | 0.27 |

We recommend a re-bolt when the gasket is brought down to room temperature.

This test has been authenticated by Yarmouth Research and Technology (www.yarmouthresearch.com).

Industrial sealing requires superior performing gaskets that can effectively retain their stability at high temperatures.

Some applications involve both high pressure and high temperature, and the right gasket for their use should match these needs with minimal chances of failure. Over the years, Durlon® High Temperature gaskets have been known to offer the required resilience as may be required on industrial-scale applications.

To get the right gasket for your high temperature application, you need to be sure of its reliability and its ability to yield optimal results. Rely on Durlon® for high performance gaskets to match your needs.

Warning: Durlon® gasket materials should never be recommended when both temperature and pressure are at the maximum listed. Properties and applications stated are typical. No applications should be undertaken by anyone without independent study and evaluation for suitability. Never use more than one gasket in one flange joint and never reuse a gasket. Improper use or gasket selection could cause property damage and/or serious injury. Data reported is a compilation of field testing, field service reports and/or in-house testing. While the utmost care has gone into publishing the information contained herein, we assume no responsibility for errors. Specifications and information contained within are subject to change without notice. This edition cancels and renders all previous editions obsolete.