Summer Vacation

We hope you’ve been enjoying the summer weather, with plenty of sunshine to get us all up and active and enjoying the great outdoors – Gus the Gasket Guru sure has…check out the comic strip!

We’re featuring a new Durlon SEALutions video on the “How to’s” of using the igasket+ app…have you downloaded the app to your mobile device? Check it out to get quick answers to your technical questions “on the go”.

Also want to give a “shout out” to all FSA members (or wannabe members) to view the unveiling of the new Fluid Sealing Association website on September 1st!

Sylvia Flegg, Marketing Manager

Tank Car 101

Cited: Railway Supply Institute

The first rail tank cars were simple, wooden containers mounted atop flat cars. They carried liquid products across North America. Modern tank cars are constructed of fine-grain heat-treated steel and incorporate a variety of safety features to improve their puncture resistance.

Types of Tank Cars

GENERAL PURPOSE tank cars are non-pressure cars that can be used to carry almost any type of material. These materials can be regulated or non-regulated commodities. The DOT-111 is the most commonly known general-purpose tank car. In flammable liquids service, the DOT-111 is being replaced by the new DOT-117 standard cars. AAR-211s are the AAR equivalent of the DOT-111 standard and are typically used in non-regulated service.

PRESSURE tank cars – designated by the DOT-105 and DOT-112 standard specifications are used to transport liquefied compressed gases under pressure, as well as some low-pressure, high-hazard materials.

What Does a Tank Car Carry?

From food products to clay slurry, chemicals to crude oil, tank cars are a workhorse of the American economy, bringing vital products to market. There are two general types of commodities that are transported: non-regulated and “hazmats,” which are hazardous materials regulated by the U.S. Department of Transportation.

Rail Safety

Railroad accidents involving tank cars carrying hazardous materials occur at very low rates. More than 99.99 percent of all railroad shipments of hazardous materials reach their destination without incident. While train accidents are rare, most are attributed to just two causes: human factors or track issues. When accidents occur, the safety features of tank cars help mitigate the effects, contain product and reduce the chance of release.

Sealing Solutions for Railway Transportation

From food products to clay slurry, chemicals to crude oil, tank cars are a workhorse of the global economy, bringing vital products to market.

Durlon rail-tank car gaskets are engineered to address the challenges related to safe railway transportation of many commodities and hazardous chemicals. From manway lids to bottom outlet valves and flange connections, Durlon provides fluid sealing solutions for numerous tank-car applications.

Non-Accident Releases, or NARs, oftentimes result in costly and potentially dangerous situations. With a focus on eliminating NARs, Durlon rail-tank car gaskets give tank-car manufactures, lessors, shippers, and repair shops the fleet flexibility and process safety needed to combat these challenges. Reducing product loss helps increase safety and reduces possible environmental effects.

Download our Durlon Railroad Tank Car Technical Handbook.

Barium sulfate fillers are homogeneously blended with pure PTFE resins to give Durlon® 9200 its physical and mechanical properties. Testing shows the fillers to be more evenly dispersed than filled PTFE with layered construction (HS-10 manufacturing method). The result is more consistent physical and mechanical properties without the voids, separation, and chemical compatibility problems found in layered filled PTFE.

Industry Applications:

- Chemical Processing

- Food & Beverage

- General/Heavy Industry

- Marine

- Mining

- OEM Services

- Oil & Gas

- Petrochemical

- Pharmaceutical

- Power Generation

- Pulp & Paper

- Rail Tank Car

- Water & Wastewater

Certifications

Durlon® 9200 – Conforms to the requirements of 21 CFR 177.1550 for food and drug contact, approved material by TA-luft (VDI Guideline 2440), passed the BAM oxygen service: gaseous & liquid up to 260°C (500°F) at 52 bar (754 psi), approved material for chlorine ins., DNV-GL ABS-PDA & Pamphlet 95, compliant with RoHS Reach Declaration.

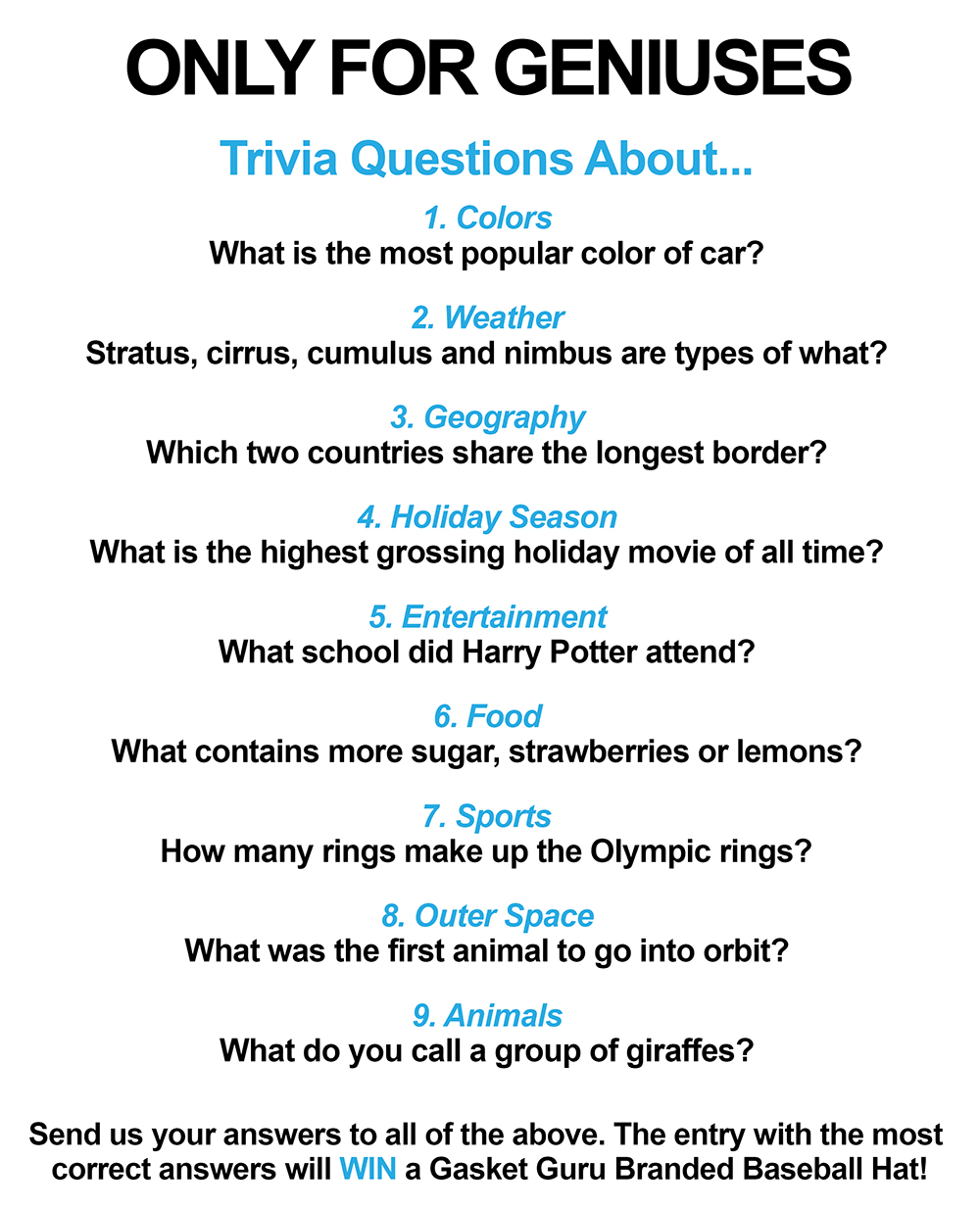

1. White, 2. Clouds, 3. The United States and Canada, 4. Home Alone, 5. Hogwarts, 6. Lemons, 7. Five, 8. A dog, 9. A tower

The Fluid Sealing Association

Unveiling a brand NEW website on Sept 1st!!

Founded in 1933, the FSA is an international trade association. Member companies are involved in the production and marketing of a wide range of fluid sealing devices primarily targeted to the industrial market. FSA members account for a majority of the manufacturing capacity for fluid sealing and containment devices in the Americas market. Learn more.

Industry Tradeshows

MINExpo International

Sep 13-15, 2021, Las Vegas, Nevada

The Global Energy Show

Sep 21-23, 2021, Calgary, Alberta

Valve World Americas

Oct 13-14, 2021, Houston, Texas

Next issue highlights: Industry and product focus. We’ll share a new video, news, and upcoming events you may want to look into. And of course, we will put those genius brains to the work again and tickle your funny bone with another adventure from our gasket guru. See you in November 2021!