Beginnings of a New Decade

Welcome to our first newsletter for 2020!

We have an exciting year ahead of us and can’t wait to share all the new developments. With the addition of new machinery on the shop floor, we will be able to offer more customization and eliminate time consuming tasks. Look for our new “Capabilities” page, coming soon!

All the videos of our 4-part informative SEALutions series is now available on our website and YouTube channel and we will begin production of 4 more for 2020…look for the roll-out!

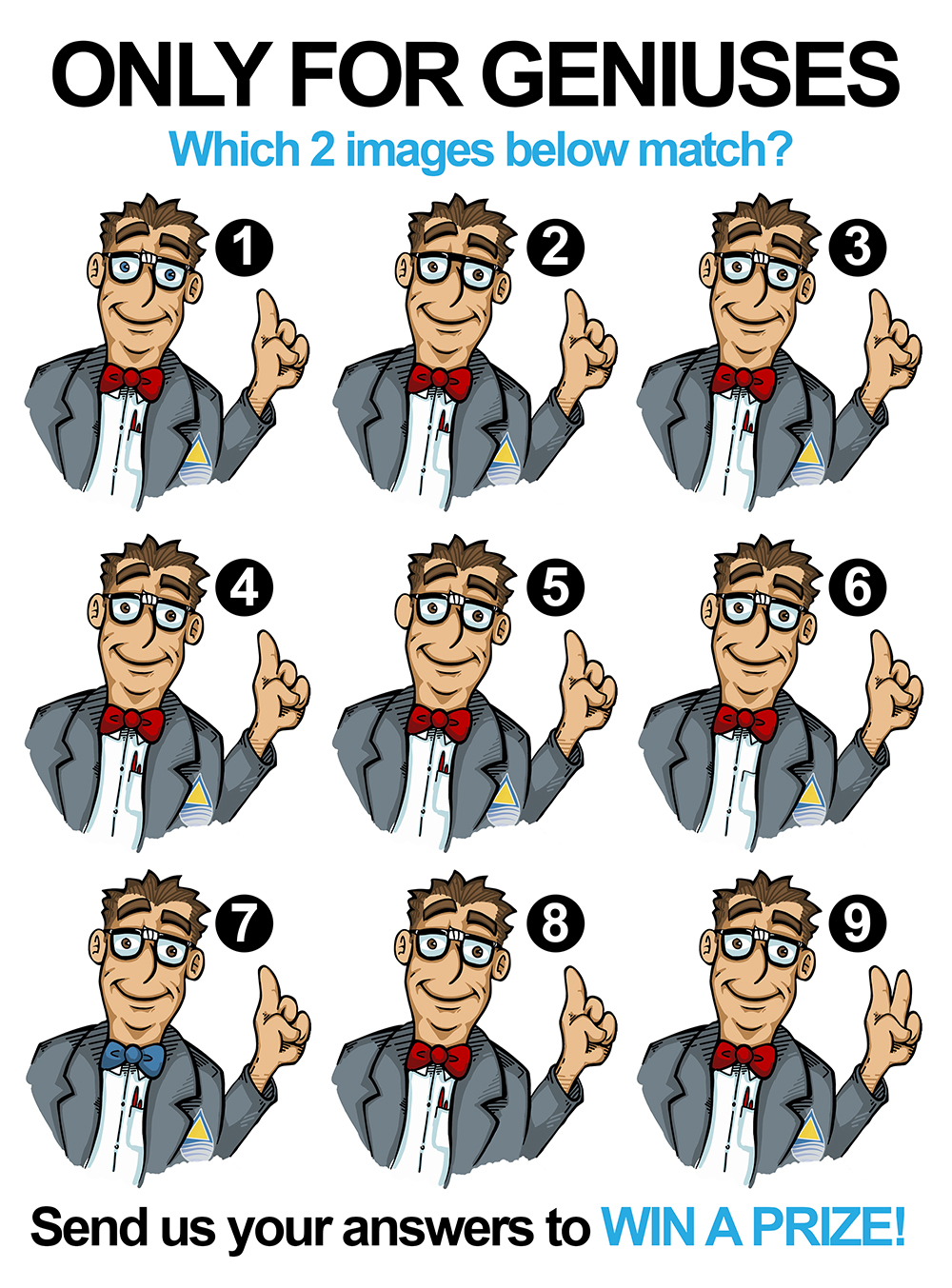

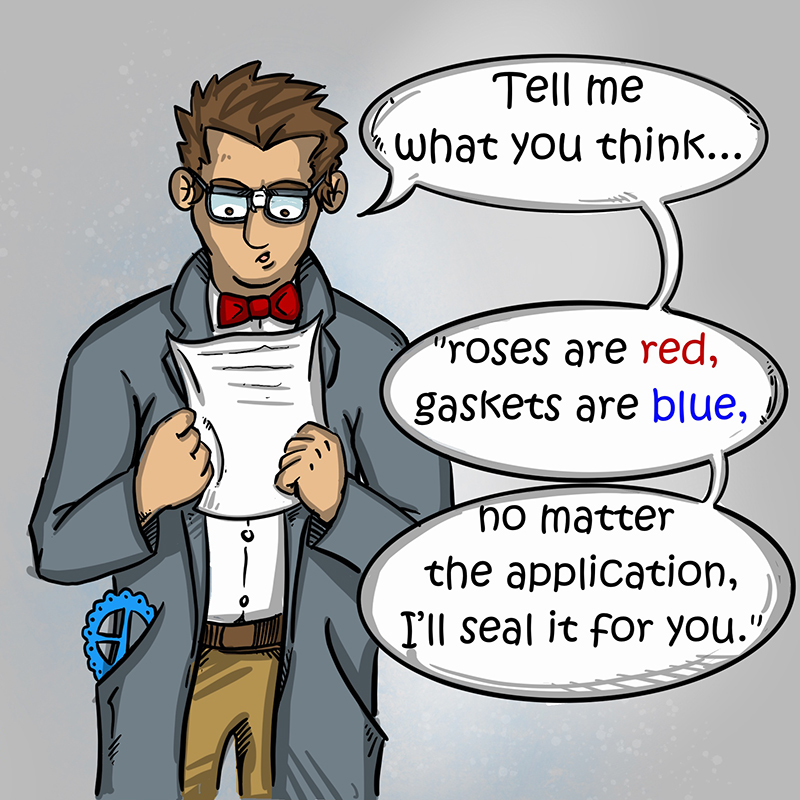

Try solving the new quiz & check out what Gus is up to!

Sylvia Flegg, Marketing Manager

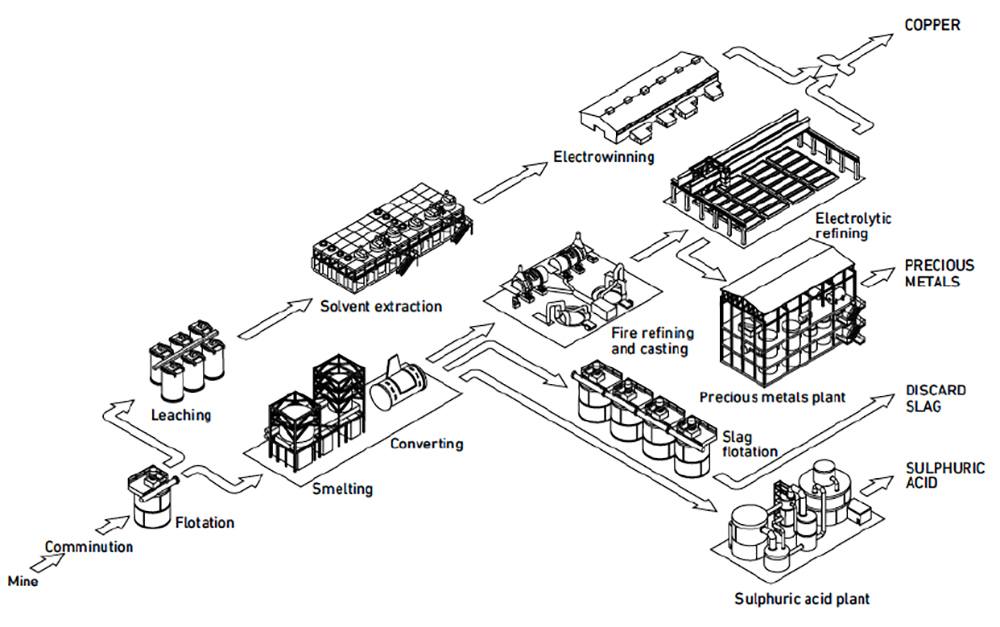

Durlon provides a reliable product that will extend service life in mining applications; primarily focused on refining and smelting from the crushing process to leaching and purification of the minerals. When you are in the business of supplying raw materials, Durlon understands your need for heavy-duty sealing solutions. We have sealing products that are reliable in even the most formidable conditions and high-pressure environments.

Above is an example of the four major processing components that produce copper:

A crushing plant reduces the ore size

A heap-leach operation dissolves the copper, using chemical and bacteriological agents

A solvent extraction plant concentrates and purifies the dissolved copper in the leach solutions

An electrowinning plant produces high-grade, high-quality cathode copper

The smelter for sulfide ores produces sulfur dioxide gas. This is scrubbed from the flue gases to make sulfuric acid for leaching copper from oxide ores. Scrubbing sulfur dioxide also protects the environment.

Copper Mining

The following gives an overview of how copper is extracted from its ore and converted into pure metal.

Mining

The ore is removed from the ground in either open pit or underground mines. Underground – sinking a vertical shaft into the earth to reach the copper ore and driving horizontal tunnels into the ore. Open-pit – 90% of ore is mined using the open pit method. Ores near the surface can be quarried after removal of the surface layers.

The ore

An ore is a rock that contains enough metal to make it worthwhile extracting.

Grinding

The ore is crushed, then ground into powder.

Concentrating

The ore is enriched using a process called froth flotation. Unwanted material (called gangue) sinks to the bottom and is removed.

Roasting

This is where the chemical reactions start. The powdered, enriched ore is heated in air between 500°C and 700°C to remove some sulphur and dry the ore, which is still a solid called calcine.

Smelting with fluxes

A flux is a substance which is added to the ore to make it melt more easily. The solid calcine is heated to 1200°C and melts. Some impurities are removed forming a matte (a mixture of liquid copper and iron sulphide).

Conversion of matte

Air is blown into the liquid matte forming blister copper, so called because the gas bubbles trapped in the solid form blisters on the surface.

Anode casting

The blister is cast into anodes for electrolysis.

Electrolytic refining

The copper is purified to 99.99% by electrolysis.

The production route described above shows the progression from a rock containing about 0.2% copper to a copper cathode of 99.99% purity.

Leaching

Leaching offers an alternative to copper mining. First, the ore is treated with dilute sulphuric acid. This trickles slowly down through the ore, over a period of months, dissolving copper to form a weak solution of copper sulphate. The copper is then recovered by electrolysis. This process is known as SX-EW (solvent extraction/electrowinning).

Advantages of these processes are:

- Much less energy is used than in traditional mining

- No waste gases are given off

- Low capital investment

- Ability to be operated economically on a small scale.

Durlon® ETG (Extreme Temperature Gasket)

have been engineered to provide the preeminent solution to sealing gasketed joints having exposure to high temperatures, typically greater than 650°C (1,200°F) and up to 1,000°C (1,800°F). At extreme temperatures, flange assembly torque retention is the key component to maintaining a tight seal, particularly during the leaching process in mining.

Durlon® ETG has combined an oxidation boundary material with the excellent stability and sealing characteristics of flexible graphite in order to preserve seal integrity and to retain the initial assembly torque.

Composition:

The Durlon® ETG’s engineered design principle is focused around providing oxidation protection zones around the central oxidation inhibited flexible graphite sealing component. Standard industrial grade flexible graphite typically begins to rapidly oxidize at around 650°C (1,200°F). By adding oxidation inhibitors to the graphite, the rate and amount of oxidation can be significantly reduced which can extend the seal life of the material, however, oxidation still occurs and at extreme temperatures it can be fatal to the integrity of the joint. Durlon® ETG adds an inner and outer protection boundary in the form of a mica-phyllosilicate based sealing material called Durlon® HT1000® consists of phlogopite mica paper impregnated with an inorganic binder at less than half the binder amount found in a typical vermiculite-phyllosilicate filled product. This lower binder content allows for superior weight retention and results in ultimate extreme temperature sealing performance. The Durlon® ETG’s design is the sealing industry’s current best available technology for effectively sealing extreme temperature applications.

Download the Durlon ETG Tech Sheet.

The FSA offers many technical publications written by experienced and knowledgeable members.

Are you looking for Specifications and Recommended Practices for various media and applications? The Fluid Sealing Association offers complimentary documentation here.

The FSA Recognizing Five Years of Technical Articles on Sealing Systems and Devices. View articles here.

Welcome to the Fluid Sealing Association KnowledgeBase!

The FSA KnowledgeBase is a source of highly reliable technical information regarding seals and sealing systems – and is FREE to all who wish to set up a complimentary account. Learn more here.

Industry Tradeshows

(IFPE) International Fluid Power Expo, March 10-14, 2020, Las Vegas Convention Center, Las Vegas, NV

ConExpo, March 10-14, 2020, Las Vegas Convention Center, Las Vegas, NV

Canada Gas & LNG Exhibition & Conference, May 12-14, 2020, Vancouver Convention Centre, Vancouver, BC, Canada

Next issue highlights: Industry and product focus. We’ll share a new video, news and upcoming trade shows that you may want to look into. And of course, we will put those genius brains to the work again and tickle your funny bone with another adventure from our gasket guru. See you in May 2020!