September 25, 2020

By: Bruce Ellis, Inside Sales Consultant at Triangle Fluid Controls Ltd.

Many informative articles have been written about check valves in the past… with that being said, let’s take this discussion “Back to the Basics”. Check valves, or one-way valves, are designed to stop backflow and ultimately, to protect pumps & compressors. They are available in several styles and sizes; from 1/8” to as large as may be required.

Check valves are found in many industries, and with various types of media, ranging from municipal water to mining and natural gas.

The 3 most common types are Swing Check Valves, Double-Door Check Valves, and Silent Spring-Assisted Axial Flow:

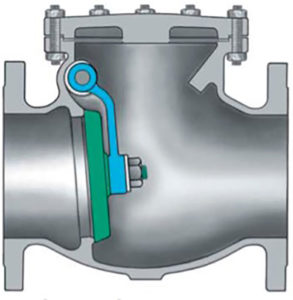

1. Swing Check Valves

Generally speaking, this is probably the most common check valve in use today and is a full-port design, meaning the disc, when fully open, is out of the flow stream. This style of check valve is a good choice in applications that have a high percentage of solids and a lower on/off cycle count. Due to the travel distance of the disc, swing check valves close slowly. This causes the last push of reverse flow to slam the disc closed, resulting in a huge pressure spike, causing Water Hammer*.

*A pressure surge when a fluid, in motion is forced to stop or change direction suddenly, causing a pressure wave in the pipe. This pressure wave can cause major problems, from noise and vibration to pipe collapse.

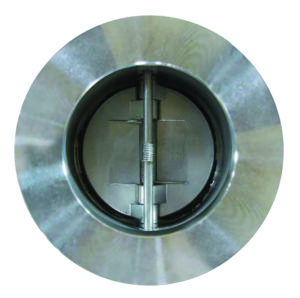

2. Double-Door Check Valve

This valve is similar to the swing check and a little better in terms of closing because of the coiled springs that assist the two cantilevered doors in closing more quickly. It has been proven time and time again that this is not the best choice when faced with Water Hammer though they will perform better than a swing check valve. Generally, this style of valve is considered an off-the-shelf commodity valve with little customization available.

3. Silent Spring Assisted Axial Flow Check Valve

These full flow valves typically incorporate a centre guided stem-disc assembly along with a compression spring. This means the disc stays in the flow stream and the media flows around it and doesn’t require manual or automated assistance to operate. When the pump is running, the valve is open; when the pump shuts off, the valve closes slightly before the reversal of fluid flow, due to the compression spring force acting on the disc, which nearly eliminates Water Hammer.

See the line-up of DFT® Silent Check Valves here.

Most requests for check valves take into consideration the line size and pressure class alone, as media pressure and flow can vary dramatically where pipe designs are oversized for future concerns or undersized due to lack of or incorrect information. This is not always the best way when deciding which style of valve to use in a system. Other things to consider are: working pressure, flow rate, the specific gravity of the media, and temperature. An analysis of the system design is highly recommended.

It is necessary to understand why valves fail, and the root causes. The most common failure is due to excessive wear of the internal parts of the valve. Springs, discs, and stems wear prematurely by not being held steady during operation. When the disc is not stable due to insufficient flow to hold it in the full-open position, chattering can occur.

Bruce Ellis is an Inside Sales Consultant at Triangle Fluid Controls Ltd. He may be reached at bruce@trianglefluid.com or 613-968-1100.

Watch for Part 2 “Check Valve Sizing” coming in December!