Triangle Fluid Controls Ltd.®, the exclusive manufacturer of Durlon® PTFE and semi-metallic gaskets, is renowned for safety, reliability, and versatility. Our Durlon® brand, recognized globally, is favored across demanding industries such as Oil & Gas, Chemical Processing, and Pharmaceuticals for its cost-saving and safety benefits.

We ensure excellence through meticulous manufacturing, rigorous on-site testing, and adherence to ISO 9001:2015 quality standards. Our advanced R&D facility and global distributor network guarantee product availability. Dedicated to exceptional customer service, we offer comprehensive training, development, and technical support to deliver outstanding value to our customers and employees.

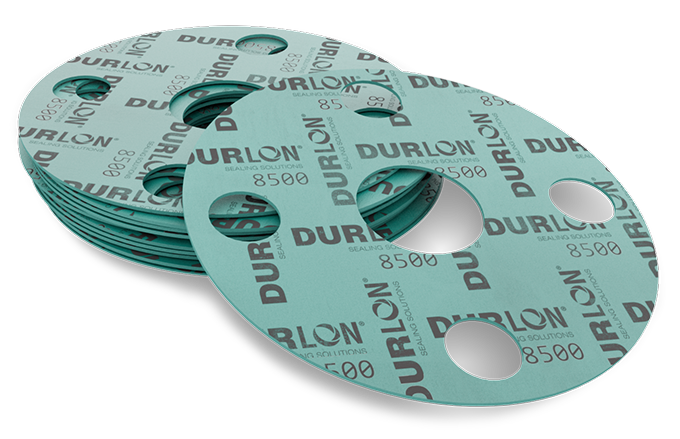

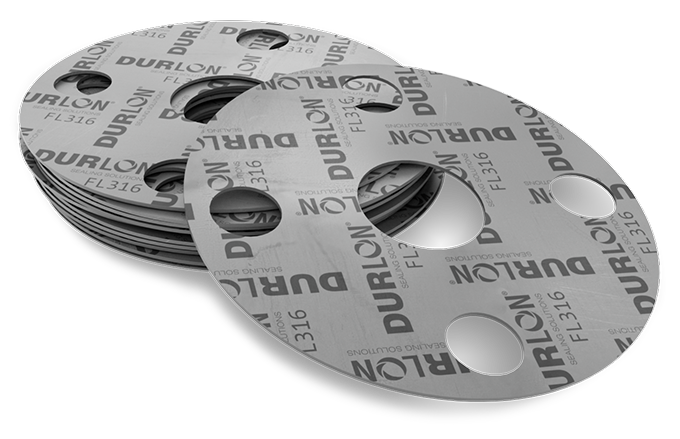

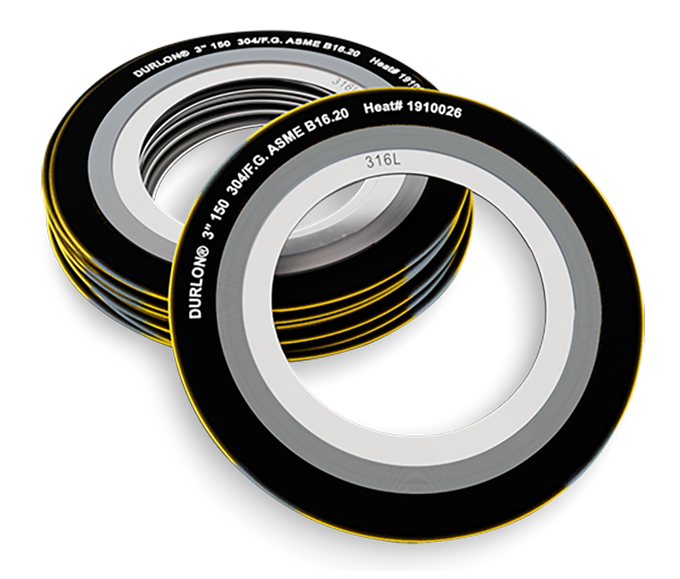

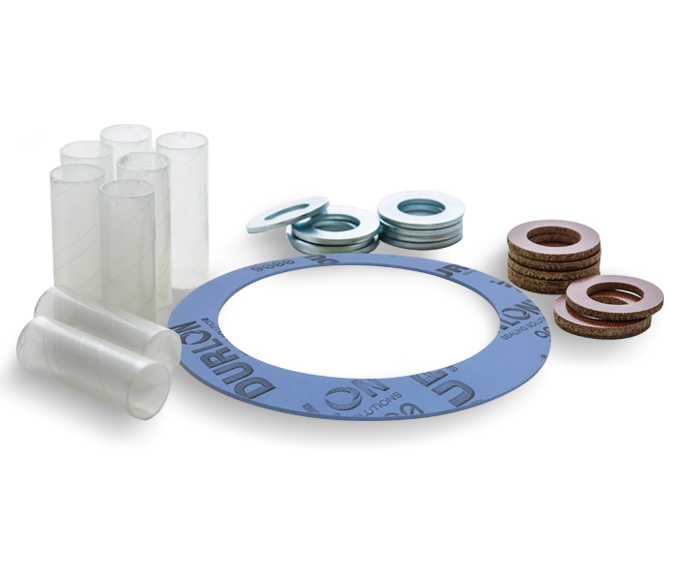

View our Durlon® gasket categories below.

MEMBERS:

Sign in to view our inventory availability, shown below.

Not a member yet?

Request an account.

Durlon® Sealing Solutions

The Durlon® product line of gaskets includes high-performance PTFE and semi-metallic gaskets known for their exceptional safety, reliability, and versatility. Our brand represents global leadership in sealing solutions with proven reliability, innovative processes, and sustainable integrity across various demanding industries, including Oil & Gas, Chemical Processing, Pulp & Paper, Mining, Power Generation, Water & Waste Water, Food & Beverage, and Pharmaceuticals.

At the core of Durlon's strengths lies an unwavering commitment to research and development, marked by continuous improvement in products and manufacturing facilities. Through the incorporation of innovative technologies and materials, we ensure cutting-edge solutions, positioning Durlon at the forefront of the industry.

Discover why Durlon® is a global leader in sealing solutions.

Gasket Application Data Form

Not sure which gasket type is required for your particular application?

Gathering detailed information about your operating conditions helps us select the perfect gasket material and design. We consider critical factors like temperature, pressure, and the type of fluid or gas being sealed so we can recommend gaskets that perform reliably and safely, minimizing the risk of leaks or failures.

A gasket application data form is essential for selecting the right gasket material and design based on specific operating conditions and fluid type. It ensures reliable and safe performance, allows for customization to meet unique needs, provides a basis for expert technical support, and aids in tracking gasket performance for maintenance and quality assurance.

By filling out a gasket application data form, you're ensuring the best possible performance for your sealing needs.