Gas problems? No need to raise a stink!

May 31, 2016

By: Bruce Ellis

If you work in natural gas processing and refrigeration, chances are you know the demands of storing and transporting gas. Compared to fluid sealing and discharge, the media flow isn’t steady, instead, gas “pulses” (through a pipeline) from a reciprocating compressor. This pulsating flow created by the compressor causes the discharge valves to chatter, and while the sound may not be high on your daily list of concerns, the resulting wear or damage to your check valve and downstream components can eventually lead to costly headaches. With the ever increasing global demand for natural gas, issues with check valves and piping systems after installation of a reciprocating compressor is something we see occurring more frequently.

The problem: an ineffective check valve for gas applications.

With natural gas production set to double by 2017 (U.S Energy Information Administration), producers must ensure that their systems are designed with quality parts. While sourcing quality equipment can be time consuming and result in large up-front costs, having the right parts installed in your system will ensure less time spent on maintenance, downtime, and fewer future costs. Ineffective discharge valves are more likely to create issues and suffer undue wear than using a check valve built with a damped design to control the valve’s moving parts. It’s not unheard of to learn of parts that have broken off of valves, damaging downstream components which may cause system failure.

Built specifically for gas applications, DFT’s PDC check valve is a world-class solution found in oil refineries, gas pipelines, as well as storage and pump stations. Its pulse dampening chamber keeps the disc stable and in place (see below video). The PDC is also self-sizing, meaning it can handle different pressures and flow rates, without creating an issue or suffering undue wear. This flexibility extends the life of the valve. As an added benefit, the PDC can protect downstream equipment from damage that could be attributed to other types of valves if they fail.

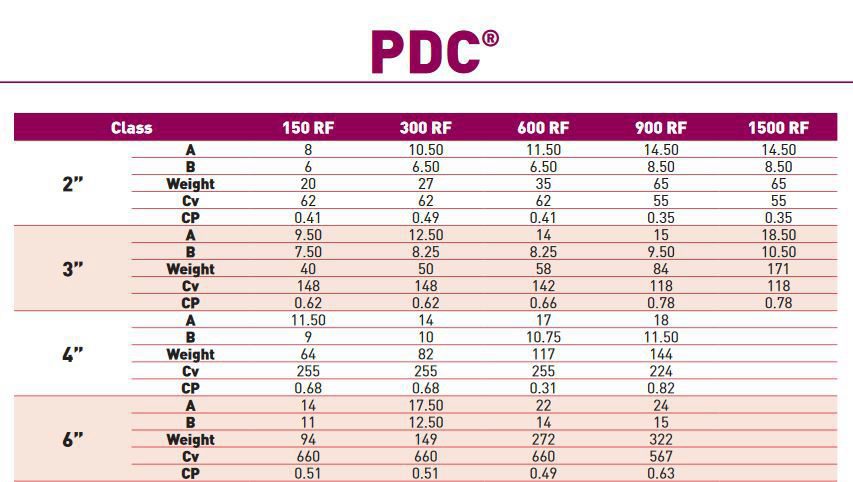

The PDC check valve is manufactured to meet industry standards and can be built and tested to meet your company’s specifications. Available in various sizes and pressure classes, it can be manufactured using various metals, and is available with flanged, butt weld, or RTJ ends. If you would like to discuss your design needs, call us toll-free at 1-866-537-1133 or email bruce@trianglefluid.com.

Dimensions:

Additional Resources:

DFT Catalogue

Valve Data Sheet

Do you have an interesting idea for an industrial blog topic you would like to see covered? E-mail stephanie@trianglefluid.com.