Feb 14, 2019

By: Michael Pawlowski, Laboratory Technologist

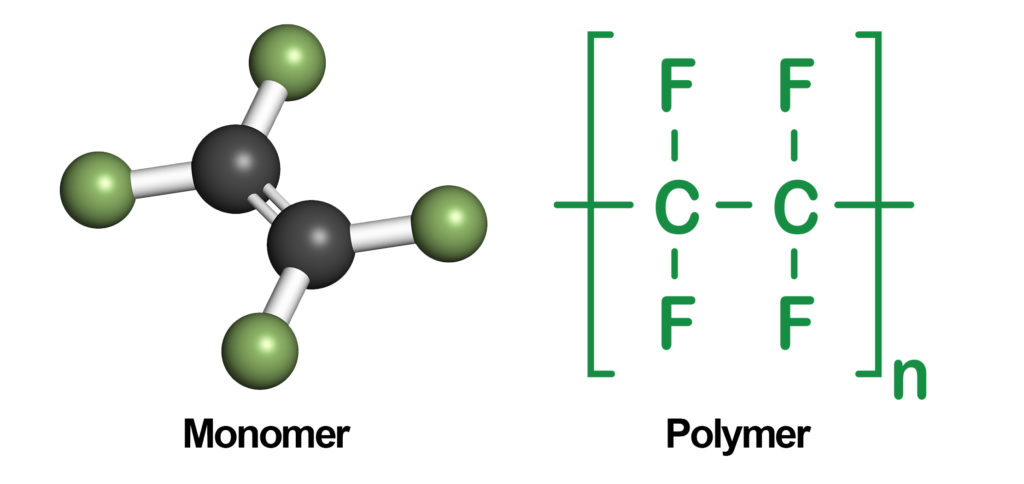

From interplanetary deep space missions to sealing the fittings between the faucets and pipes in your kitchen sink, Polytetrafluoroethylene (PTFE) can be found being used in almost every aspect of our daily lives. It was discovered accidentally April 6, 1938 by Dr. Roy J. Plunkett while running experiments utilizing gasses for freon refrigeration. The white waxy substance that had spontaneously polymerised was found to have some remarkable properties. PTFE turned out to be a resin impervious to almost every known solvent with a near frictionless surface which no substance would stick to.

The unique properties of PTFE lend itself well for use in a variety of industrial, manufacturing, and engineering facilities. The superb chemical resistance and tolerance to vast temperature gradients has not only improved the efficiency of many industries but the safety for the employees that work around those conditions as well.

12 ADVANTAGES OF USING PTFE FILLED COMPOUNDS

- Excellent chemical resistance

- Wide range of service temperature

- Excellent dielectric properties

- Non-stick, low friction

- No embrittlement or ageing

- Smooth surface finish can be achieved

- Non wetting

- Outstanding corrosion protection

- Electrical insulation

- High thermal stability and flame resistance

- Resistance to weathering

- Food grade compliancy

5 COMMON GRADES OF PTFE

Virgin PTFE

“Virgin PTFE” (PTFE without a filler) is one of the most chemically inert materials known and is used in many different applications and industries.

Glass Filled PTFE

Virgin PTFE with 20-30% Glass fiber filler which dramatically increases compressive strength and lowers deformation under load.

Bronze Filled PTFE

The addition of Bronze to PTFE gives better dimensional stability and lowers creep, cold flow and wear.

Carbon Filled PTFE

The addition of Carbon Fibre to PTFE increases the compressive strength and wear resistance. It provides good thermal conductivity and low permeability.

Stainless Steel Filled PTFE

The material is extremely hard wearing, has excellent strength and stability under extreme loads and elevated temperatures whilst still retaining the low coefficient of friction of conventional PTFE.

PROCESSING PTFE

Because PTFE is a thermoplastic and due to its high viscosity, it cannot be processed using conventional polymer processing techniques. PTFE is processed by cold shaping and followed by heat treatment (sintering) during which polymer particles fuse to form a solid moulding.

PTFE is highly resistant to corrosion due to its chemical inertness. Unfortunately, that same chemical inertness prevents PTFE from being cross-linked like elastomers and is subject to the phenomenon of cold-flow – otherwise known as “creep”. To reduce and diminish cold-flow, additives are introduced during the preparation of PTFE compounds. Fillers, such as glass fiber found in Durlon® 9000 and 9000N gaskets, not only reduce creep but also maintain chemical inertness against aggressive and caustic chemicals but are still considered safe for use by food, drug and medical services.

Durlon® 9000 & 9000N PTFE SHEETS & GASKETS

Various shapes of inorganic fillers have been homogeneously blended with pure PTFE resins to give Durlon® 9000 its physical and mechanical properties. It is suitable for use in steel flanges and will not exhibit the cold flow problems associated with virgin PTFE or the hardness problems of some other filled PTFE products. It cuts easily and separates cleanly from flanges after use.

Certifications

Durlon® 9000 – API Standard 6FA Fire Test, TA-Luft (VDI 2440), BAM, Pamphlet 95 (Chlorine Institute), FDA Compiant, USP Class VI Certified, ABS-PDA Certified, EC 1935/2004 Compliant, DNV-GL Accreditation, RoHS Reach Declaration

Durlon® 9000N – FDA compliant, ABS-PDA Certified, USP Class VI Certified, RoHS Reach Declaration

Durlon® 9000 is made with Teflon™ fluoroplastic. Teflon™ is a trademark of The Chemours Company FC, LLC used under license by Triangle Fluid Controls Ltd.