New Screen Reveal Coming soon!

We’re changing up our product photos and introducing high-tech computer generated ones…so check back soon to experience a new digital screen reveal!

We have many exciting projects that will be released in the next few months – videos, blogs, literature, new website features and much more! If you’d like to stay up to date, follow us on Twitter and LinkedIn!

Be sure to check out the comic strip to see what Gus has gotten himself into and don’t forget to enter your answers for a chance to win a Gasket Guru baseball hat!

Austin Boyd, Marketing Coordinator

Why Spiral Wound Gaskets?

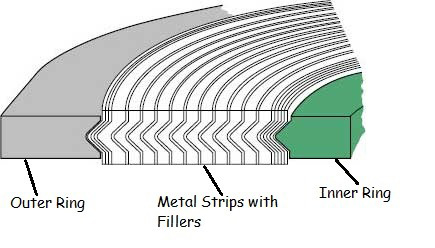

Spiral wound gaskets for flanges feature a metal sealing element filled with graphite, PTFE, or a temperature resistance inorganic filler. For this reason, spiral wound gaskets are classified as “semi-metallic” gaskets.

The metal component of the spiral wound gasket provides strength to the seal, whereas the fillers provide sealability, and enhance the gasket’s conformability and resilience. Inner and centering rings can be added to the core sealing element depending on the application. A centering ring facilitates the gasket installation, and an inner ring provides extra support to the gasket against inward buckling. Spiral wound gaskets with graphite fillers are the most commonly sold type.

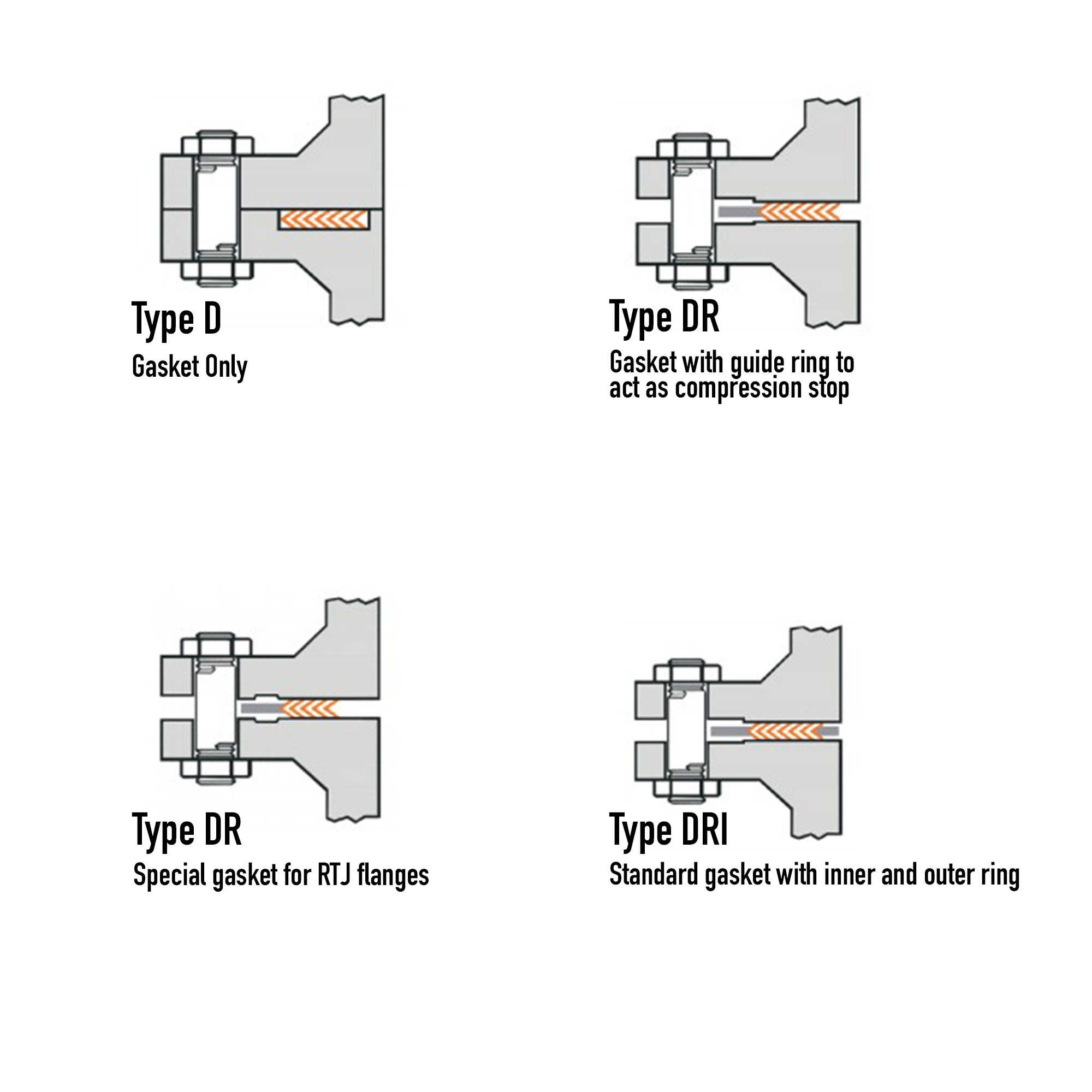

Spiral Wound Gasket Types

A few different types of spiral wound gaskets exist. Spiral wound gasket choice may vary depending on: the metal winding, filler, and ring materials, the presence of rings (outer and inner) and the materials of the inner and the outer ring of the gasket.

Type D:

Spiral Wound Gasket without rings:

Used for tongue and groove, male and female flanges. Can also be supplied with inner ring as Type DI.

Type DR:

Spiral Wound Gasket with outer ring:

Used for raised face and full face flanges.

Type DRI:

Spiral Wound Gasket with inner and outer rings:

Used for raised face and full face flanges. As well as worn RTJ replacement gaskets.

Special Section:

Spiral Wound Gasket with special rings:

Used for special flanges and special usage. Each manufacturer, of course, has specific codes to designate the different spiral wound gasket types, but the typical designs are

recurring regardless of the producer. This image shows how the different spiral wound gasket types used for flanged joints in piping applications:

Spiral Winding Materials

The sealing element of a spiral wound gasket is produced by interleaving plies of alternating metal winding strip combined with a filler material. The filler material is the key sealing element of this type of semi-metallic gasket, and works hand in hand with the metal winding to produce a strong, tight seal.. The most common winding materials are:

SS 304L, SS 316L, SS 321, SS 347, duplex and Nickel alloys

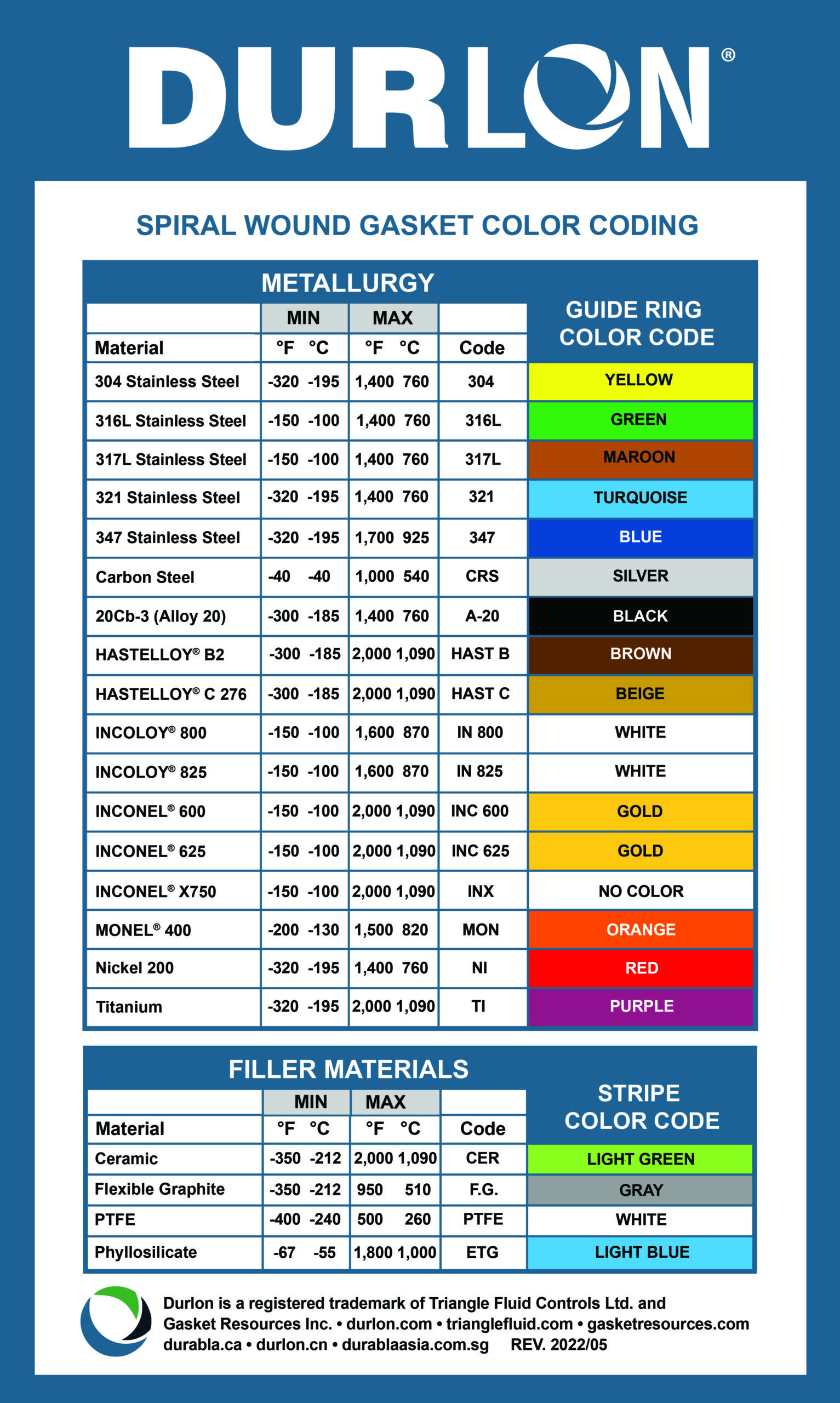

Spiral Wound Gasket Colors

Spiral wound gaskets made with different windings and filler materials are easy to spot, as each combination is designated by the application of color codes (the main color designates the winding materials, the stripes indicate the type of filler):

Metallic winding materials:

The metallic winding material is designated by a solid color identification around the outside edge of the centering ring.

Non-metallic filler color coding:

the gasket filler materials are designated by a number of stripes placed at equal distances around the edge of the centering ring

Filler Materials

Filler materials are used to enhance the conformability and the resilience of a spiral wound gasket. The most used filler material is graphite, however, other filler materials may be used depending on the application:

Graphite

PTFE

Ceramic fibers

Non-asbestos

Inner and Outer Rings Materials (The inner ring should match the winding material, with the outer ring usually being an epoxy coated carbon steel, Higher grade steel can be used upon customer request.)

Solid inner rings are required by the ASME B16.20 specification for flanges with pressure rating 900# NPS 24 and larger, 1500# NPS 12 and larger, pressure class 2500#, NPS 4 and larger.he inner ring improves the pressure rating of the spiral wound gasket, as it provides additional compression to the flanged joint and provides a heat and corrosion barrier protecting the gasket windings and the flanges from erosion.

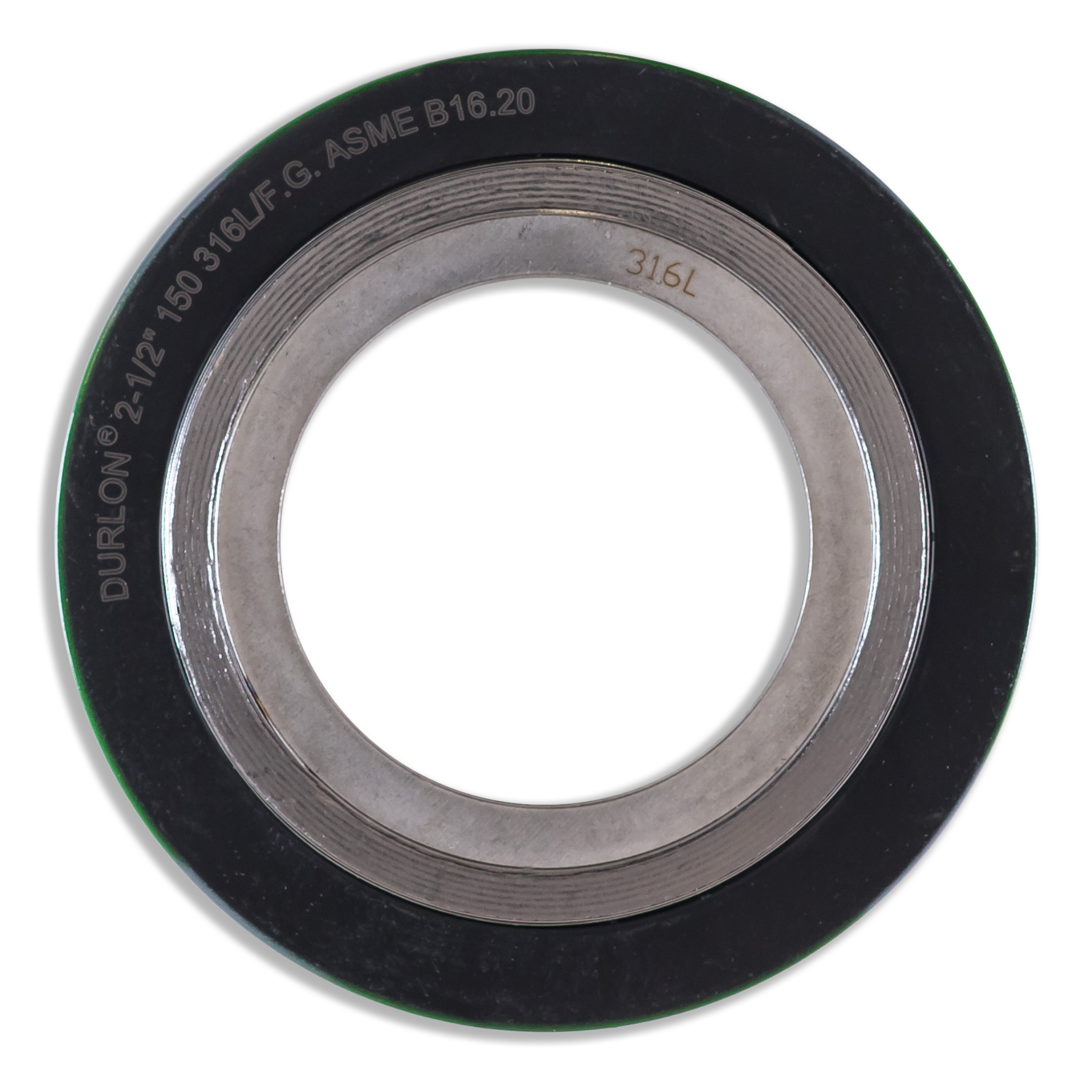

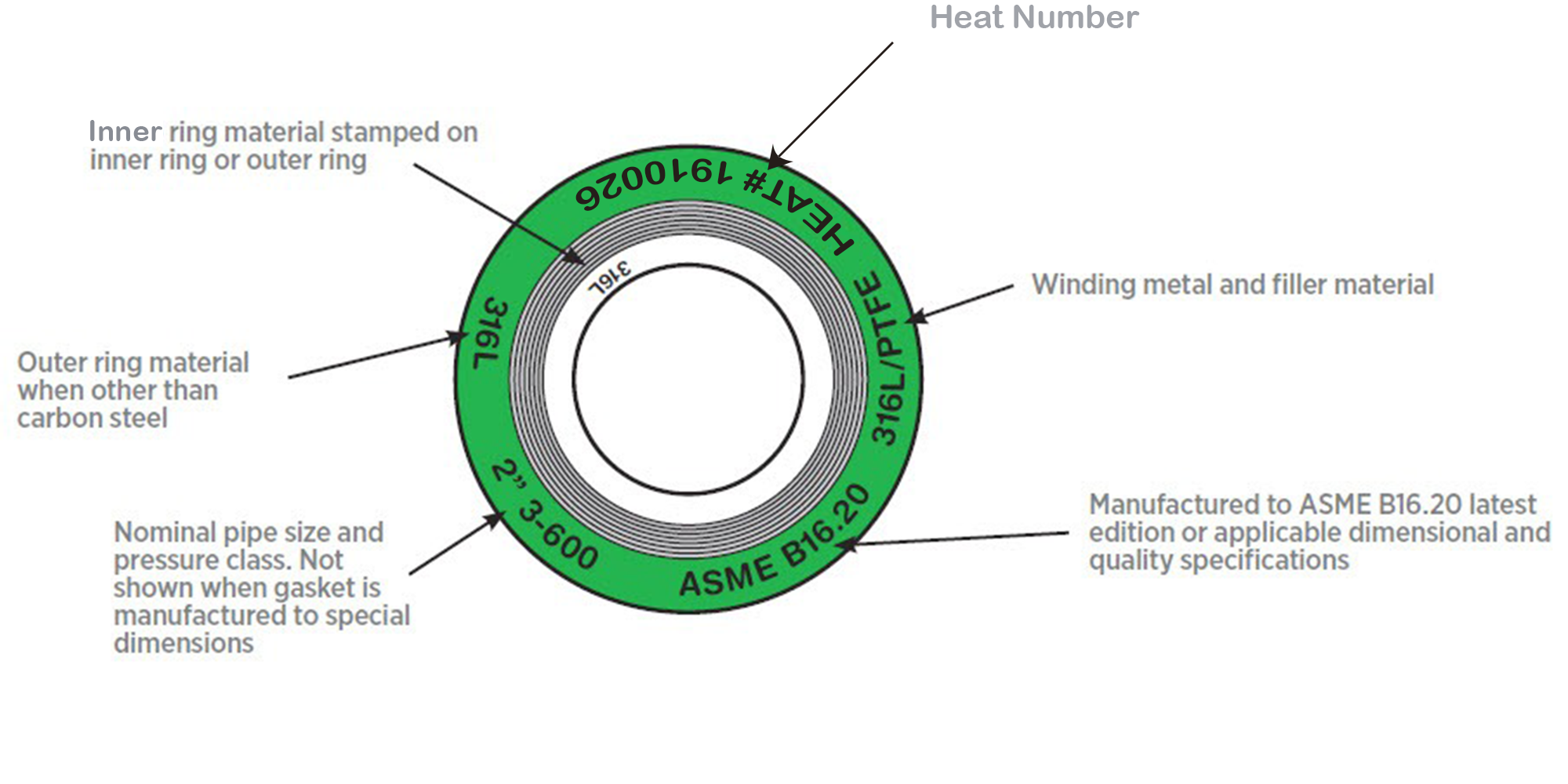

Spiral Wound Gasket Marking

The illustration Below shows the typical marking of spiral wound gaskets:

Learn more on page(s) 40-41 of the Durlon Gasket Manual.

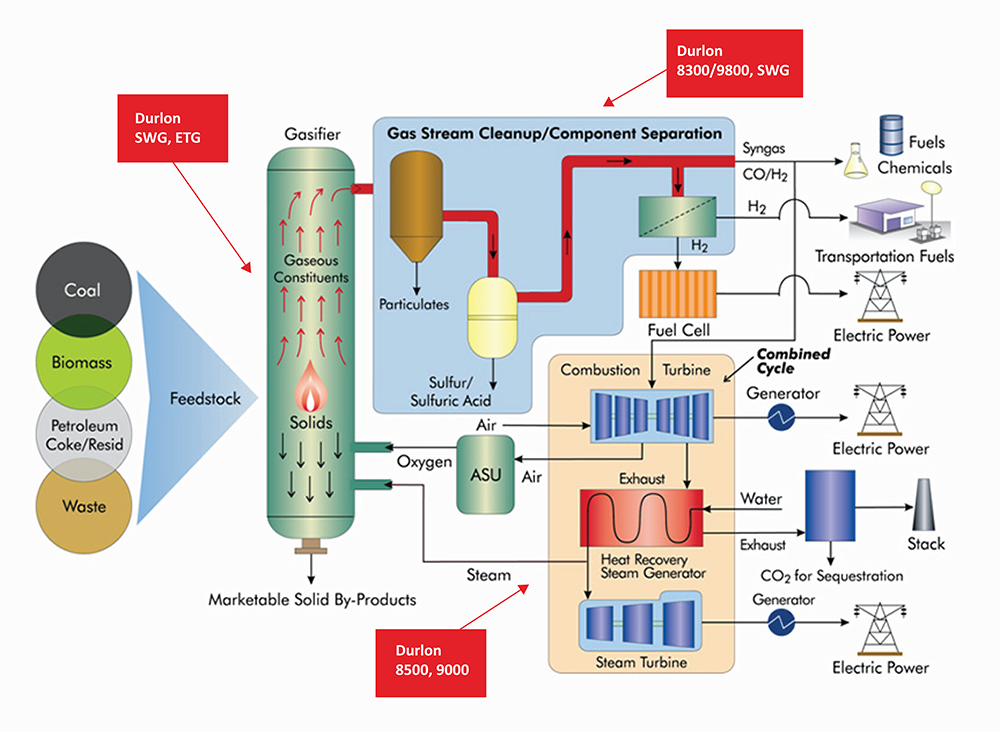

What Is Gasification

What is Gasification

Gasification can convert municipal solid waste into energy and valuable chemical products. It’s a clean alternative to conventional incineration and works in a fundamentally different way. Incinerators use large amounts of air to burn municipal solid waste, producing pollutants that can only be cleaned up after combustion, leaving behind ash that must be carefully disposed of. The heat generated by incinerators is used to make steam and generate electricity. Gasification doesn’t burn the municipal solid waste. Instead, it breaks the molecules apart with heat and a very small amount of air or oxygen, and then recombines them to form syngas, a clean fuel similar to natural gas. It’s these chemical reactions that make gasification so different from incineration. The syngas can be used to make fuels, chemicals, fertilizers, and consumer products as well as generate electricity.

Below is a diagram (sourced from: https://netl.doe.gov) showing the gasification process and where our Durlon® products can be used.

Industry Trade Shows

Turbomachinery & Pump Symposia – Sept 13-15, 2022

A forum for the exchange of ideas between rotating equipment engineers and technicians worldwide.

George R. Brown Convention Center

Houston, TX, USA

Western Canada Water (WCW22) Conference – Sept 13-16, 2022

Take in a couple of workshops, or tours and join us for three fully packed days of education, networking, and connecting.

Hyatt Regency Hotel

Calgary, AB, Canada

FSA Annual Meeting 2022 – Oct 18-20, 2022

The Fluid Sealing Association’s Annual Meeting provides members with valuable opportunities to engage and to have face-to-face discussions on the latest issues facing the industry.

Hotel Contessa

San Antonio, TX, USA

Next issue highlights: Industry and product focus. We’ll share a new video, news, and upcoming events you may want to look into. And of course, we will put those genius brains to the work again and tickle your funny bone with another adventure from our gasket guru. See you in November 2022!