Happy New Year

We have an exciting year ahead of us and can’t wait to share all the new developments…here’s a hint: “lights, camera, action!” Yes, we’re vamping up our digital collateral with fresh material that will absolutely “Wow” you. New product shots and video content will bring Durlon Sealing Solutions to the next level, both visually and creatively. We plan to share informative, industry-related, illustrated video content that will interactively describe all the many applications where our gaskets can be used.

This year we’ll be featuring additional, informative blogs, and brand new episodes of our “ever-popular” series of helpful videos – SEALutions.

Sylvia Flegg, Marketing Manager

Understanding Industrial Wastewater Treatment

Process plants generally try to minimize the amount of wastewater they generate. However, operations invariably result in the production of some wastewater. These usually contain organic and inorganic matter in varying degrees of concentration. They may include toxic and other harmful materials, as well as components that are non-biodegradable or that, can reduce the efficiency of many wastewater-treatment operations.

Main Industrial sectors that produce wastewater:

- Battery manufacturing

- Chemical manufacturing

- Electric power plants

- Food industry

- Iron and steel industry

- Metalworking

- Mines and quarries

- Nuclear industry

- Oil and gas extraction

- Petroleum refining and petrochemicals

- Pharmaceutical manufacturing

- Pulp and paper industry

- Smelters

- Textile mills

Treatment methods fall into three categories: physical, chemical and biological.

- Physical treatment methods include sedimentation, flotation, filtering, stripping, ion exchange, adsorption and other processes that remove dissolved and non-dissolved substances without necessarily changing their chemical structures.

- Chemical methods include chemical precipitation, chemical oxidation or reduction, formation of an insoluble gas followed by stripping, and other chemical reactions that involve exchanging or sharing electrons between atoms.

- Biological methods rely upon living organisms using organic or, in some instances, inorganic substances for food.

What does a wastewater treatment system typically remove?

An industrial wastewater treatment system might be made up of the technologies necessary to remove any number of the following:

- Biochemical oxygen demand – refers to the amount of dissolved oxygen needed by aerobic biological organisms to break down organic matter into smaller molecules.

- Nitrates and phosphates – If large amounts of nitrates and/or phosphates are not removed from wastewater and these nutrients are discharged into local environments, they can lead to extensive weed growth, and algae.

- Pathogens – bacteria, viruses, fungi, or any other microorganisms that can be present in wastewater that can lead to all kinds of health issues, including acute sickness, and severe digestive problems.

- Metals – when left in wastewater in high concentrations, metals can cause extensive damage to the environment and human health. They are particularly damaging because they don’t break down and tend to accumulate.

- Synthetic chemicals – when pesticides and other chemicals are used/made in the manufacturing process, they can be transmitted to humans and the environment through wastewater, causing damage to the environment and human health.

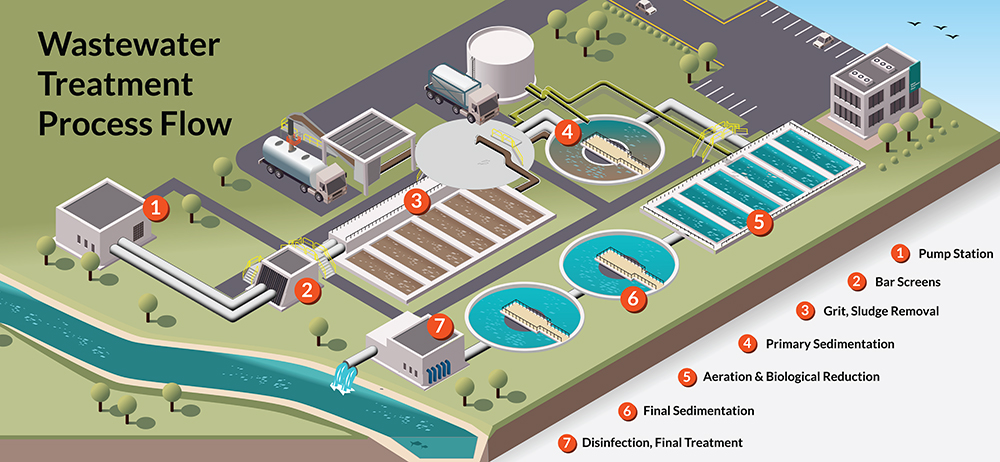

How does a wastewater treatment system work?

Specific treatment processes vary, but a typical wastewater treatment facility process will usually include the following steps:

- Coagulation – a process where various chemicals are added to a reaction tank to remove the bulk suspended solids and other various contaminants.

- Flocculation – when coagulation is complete, the water enters a flocculation chamber where the coagulated particles are slowly stirred together with long-chain polymers (charged molecules that grab all the colloidal and coagulated particles and pull them together), creating visible, settleable particles that resemble snowflakes.

- Sedimentation – is typically a large circular device where flocculated material and water flow into the chamber and circulate from the center out. In a very slow settling process, the water rises to the top and overflows at the perimeter of the clarifier, allowing the solids to settle down to the bottom of the clarifier into a sludge blanket. The solids are then raked to the center of the clarifier into a cylindrical tube where a slow mixing takes place and the sludge is pumped out of the bottom into a sludge-handling or dewatering operation. The dewatering process takes all the water out of the sludge with filter or belt presses, yielding a solid cake. The sludge water is put onto the press and runs between two belts that squeeze the water out, and the sludge is then put into a big hopper that goes to either a landfill or a place that reuses the sludge. The water from this process is typically reused and added to the front end of the clarifier.

- Filtration – running the water overflow into gravity sand filters. These filters are big areas where they put two to four feet of sand, which is a finely crushed silica sand with jagged edges. The sand is typically installed in the filter at a depth of two to four feet, where it packs tightly. The feedwater is then passed through, trapping the particles.

- Disinfection – After the water flows through the gravity sand filter, the next step is typically disinfection or chlorination to kill the bacteria in the water.

- Distribution – if the wastewater is being reused in an industrial process, it’s typically pumped into a holding tank where it can be used based on the demands of the facility.

Applications where an RCA® can be used: Agricultural chemicals, road treatment chemicals, irrigation system collections, water treatment chemicals, leachate, refinery runoff, airport deicing (glycol), medical emergency drain collection, fire fighting foam storage, paint manufacturing, pickling solutions, fish hatchery waters, pharmaceutical manufacturing sumps, leather processing chemicals, food processing liquids, potable water, cooling water, condensate return, industrial wastewater, mildly corrosive liquids, crude oil & gas, produced water, saltwater, and CO2.

Industry Applications:

- Mining

- Pulp & Paper

- Petrochemical

- Chemical Processing

Certifications

Certification applies to gasket material used.

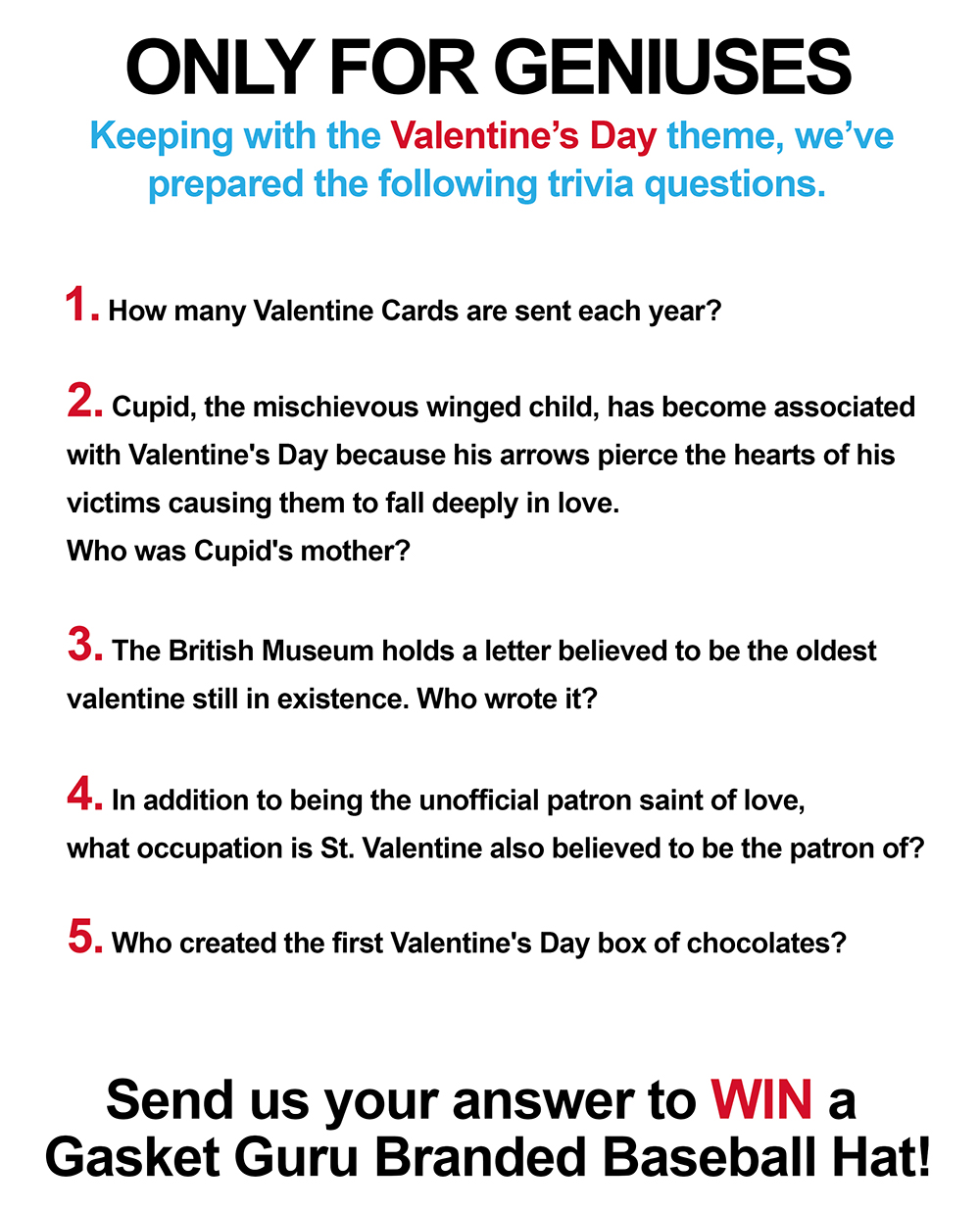

Answers:

1. One billion

2. Venus, the Goddess of Love

3. Charles d’Orléans

4. Protection of beekeepers

5. John Cadbury

WWETT Show (Water & Wastewater Equipment, Treatment & Transport)

Is the world’s largest annual trade show for wastewater and environmental service professionals.

Feb 21-24, 2022, Indiana Convention Center, Indianapolis, IN, USA

MineXchange SME Annual Conference & EXPO

Learn about advances in innovation, the critical role that rare earth elements play in shaping mining for the next decade, and managing water usage and waste throughout the project lifecycle.

Feb 27-Mar 2, 2022, Salt Palace, Salt Lake City, Utah, USA

GFA Gasketing/Converting Expo 2022

A valuable way to network and to conduct business with industry peers, and to learn about the latest technologies and innovative ideas.

Apr 27-29, 2022, Rosen Shingle Creek, Orlando, Florida, USA

Canada Gas & LNG Exhibition and Conference

The only event of its kind, CGLNG is able to adapt and reflect the expansions taking place within the market such as the recent FID on LNG Canada and bring the full value chain together.

May 10-12, 2022, Vancouver Convention Centre, Vancouver, BC, Canada

Next issue highlights: Industry and product focus. We’ll share a new video, news, and upcoming events you may want to look into. And of course, we will put those genius brains to the work again and tickle your funny bone with another adventure from our gasket guru. See you in May 2022!