July 3, 2019

By: John Anderson

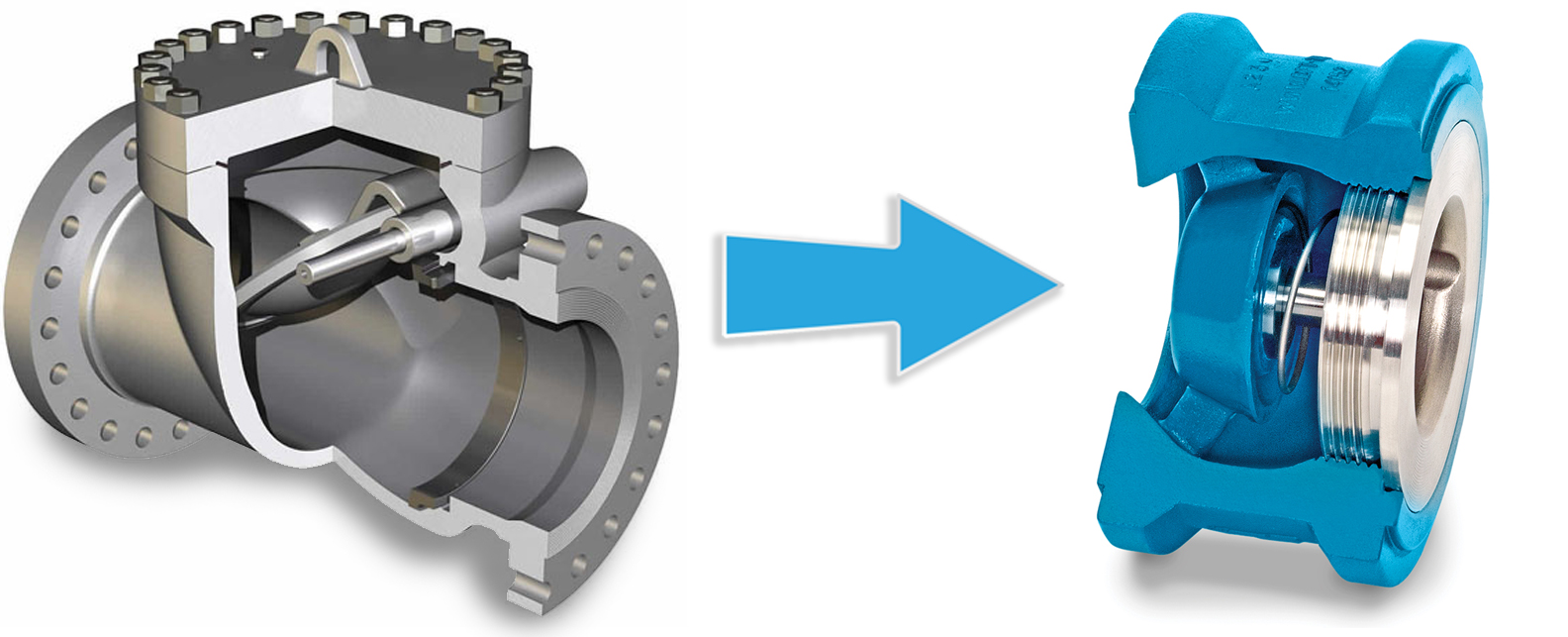

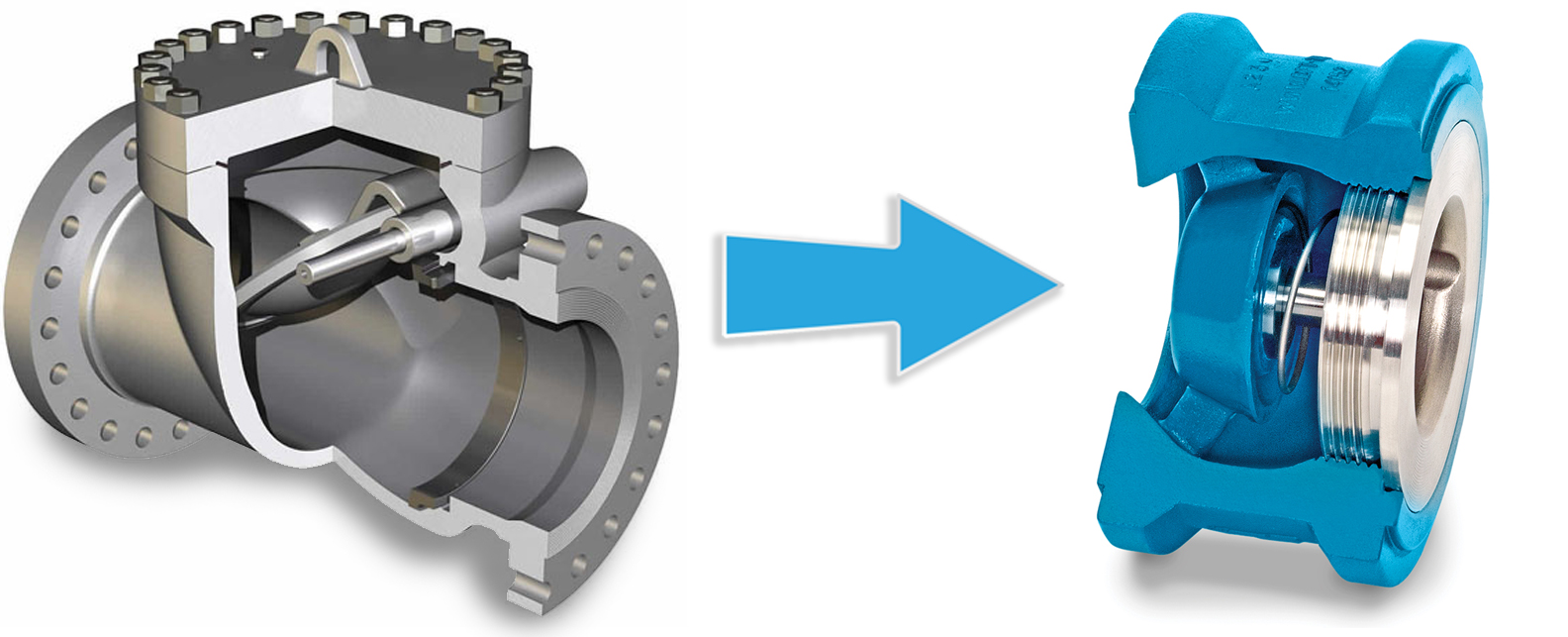

Recently, while calling on an oil and gas customer, I was illustrating the perils of using a swing check on liquid pump discharge where reverse flow and water hammer can be an issue. Part way through our conversation, the customer’s eyes lit up, and he said, “oh, that’s why I found the disk of the check valve in my sump!”. That is one of the risks that designers and maintenance people run into, when a swing check valve is misapplied on pump discharge where reverse flow and water hammer can be a problem.

When a pump trips, (due to a power failure as an example), backflow can get into the pump discharge, spinning the impellor of the pump the wrong way, and potentially damaging the pump. A check valve is typically applied to the pump discharge, to prevent this from occurring.

In a situation, that I term “light duty”, meaning that the pump is not cycling often, and there is not a large volume of media at play, (water as an example), a swing check would likely be fine in that application. However, in a situation where the pump is cycling often, and is dealing with a large volume of fluid (horizontal orientation), several things can happen, if a swing check is misapplied in this case.

Due to a phenomenon known as column separation, an inordinate amount of head comes back onto the pump when it trips. In this case, a swing check does not close quickly enough to prevent backflow from getting past the valve, and when it closes, it slams shut, and backflow behind the valve hits the disk, the energy has to dissipate somehow, and it does so in the form of water hammer. This occurs because a swing check largely depends on back flow for it to close. A non-slam check valve does not. It utilizes a coiled spring, downstream from the valve disk, that moves the disk toward the seat as soon as the flow velocity slows down. This valve is designed to be closed, just before zero flow is reached, thereby eliminating backflow. With no backflow, the cause of the water hammer disappears.

In addition, if a misapplied swing check sees a number of slamming incidents, it is possible for the hinge pin (holding the valve disk in place), to crack, and break off, thereby sending bits of metal downstream, potentially damaging components downstream of the check valve. It is also possible for the entire disk to break off, sending it downstream, leaving nothing but a spool piece.

Designers and maintenance personnel should be aware of situations where backflow and water hammer can be a problem on pump discharge and consider the use of a non-slam check valve in these cases, thereby eliminating the chance that you to may find a disk in your sump!

As the Canadian distributor of DFT® silent check valves, Triangle Fluid Controls Ltd. is proud to represent a company that is known around the world as the valve to use for preventing or eliminating Water Hammer problems – DFT® Check Valves, Serious performance, Superior reliability.